Laser crystals are one of the most critical components in solid-state laser technology. They act as the gain medium that amplifies light through stimulated emission. These precisely engineered materials have revolutionized industries like manufacturing, medicine, and scientific research. They enable applications that were unimaginable just decades ago.

Laser crystals are specialized optical crystals—usually single crystal materials—that work as the gain medium in solid-state lasers. These crystals are usually doped with trivalent rare earth ions or transition metal ions. These ions become the active centers for laser action. When external energy is supplied via optical pumping—like flash lamps or laser diodes—these dopant ions absorb the pump energy. They then emit coherent laser light through stimulated emission.

The fundamental process is simple: when pump light is absorbed by the crystal, dopant ions jump to higher energy states. These excited ions release photons coherent with incoming light. This creates the amplification effect needed for laser operation. This process lets laser crystals turn electrical or optical pump energy into highly focused, intense laser beams. These beams have exceptional precision and control.

Compared to doped glass materials, laser crystals have several big advantages:

Higher transition cross-sections—so light amplification is more efficient

Narrower absorption and emission bandwidths—allowing precise wavelength control

Better thermal conductivity—so heat dissipates better during operation

Possible birefringence properties—helpful for polarization control

Better mechanical stability and resistance to thermal stress

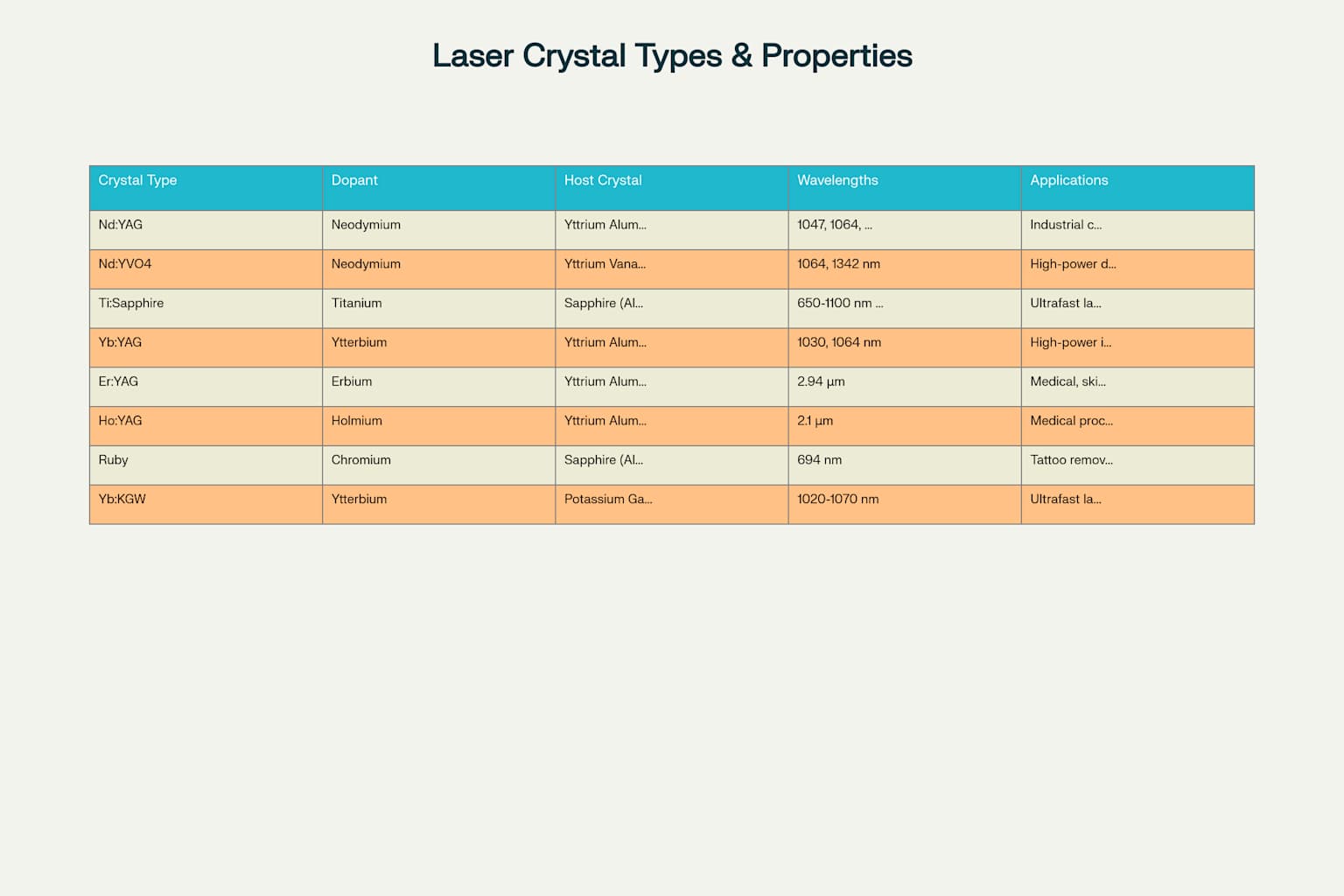

The laser crystal market has a wide range of materials. Each is optimized for specific applications and wavelength needs. In 2022, the global market was worth about $1.2 billion. It’s projected to hit $1.8 billion by 2030, growing at a 5.4% CAGR.

Laser crystals are mainly categorized by their dopant ions. These ions fall into two main groups:

Rare Earth Ions: These include neodymium (Nd³⁺), ytterbium (Yb³⁺), erbium (Er³⁺), thulium (Tm³⁺), holmium (Ho³⁺), and cerium (Ce³⁺). People like rare earth dopants because their excited states don’t couple strongly with the crystal lattice’s thermal vibrations. This means pumping thresholds are relatively low.

Transition Metal Ions: These include titanium (Ti³⁺), chromium in different oxidation states (Cr²⁺, Cr³⁺, Cr⁴⁺), and others. Transition metal dopants often have broader tuning ranges. They’re used in specialized applications.

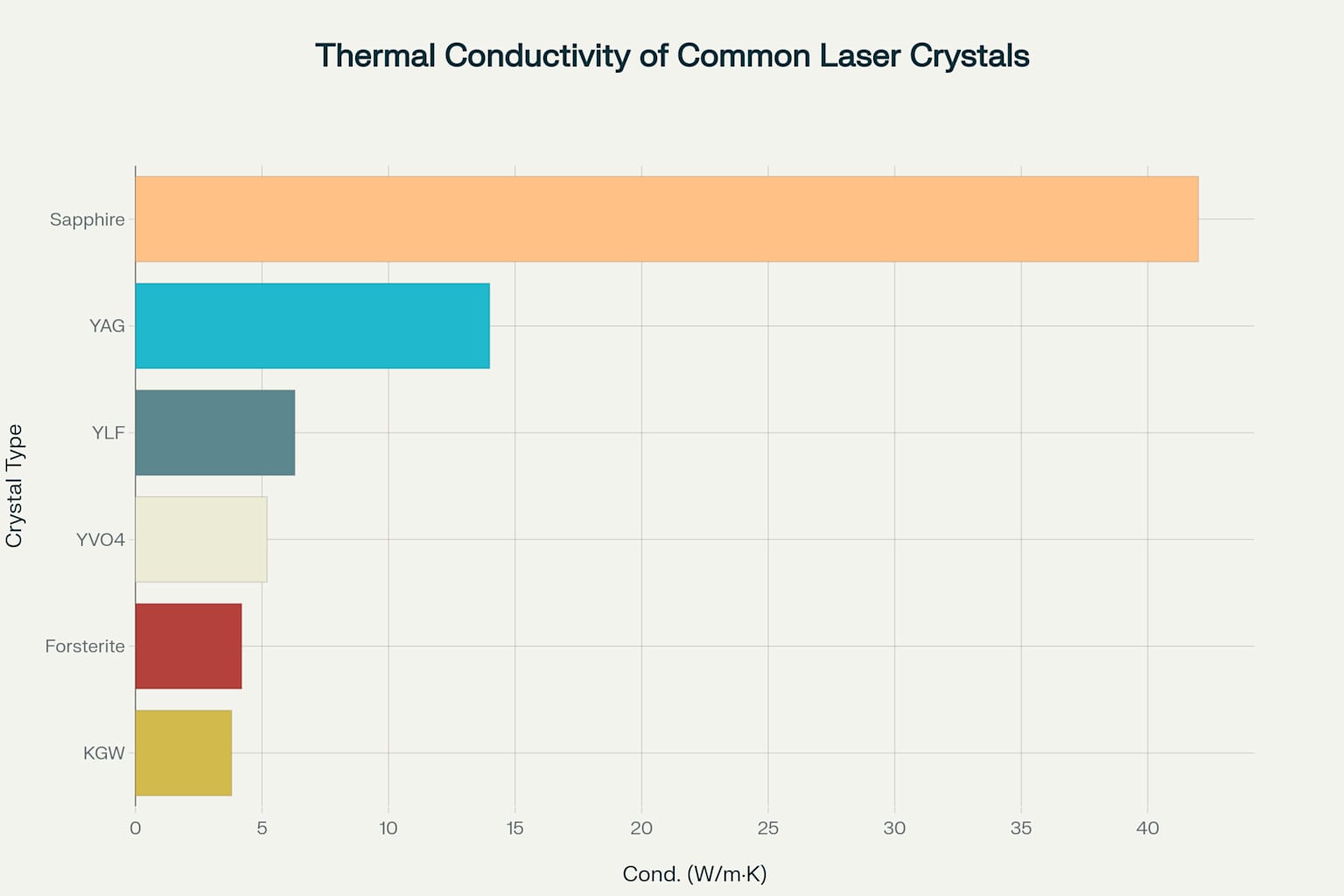

Thermal conductivity is a key parameter for laser crystal performance. This is especially true in high-power applications where heat dissipation is critical. Different crystal hosts have very different thermal properties. These properties directly affect how suitable they are for various laser setups.

For example, sapphire has exceptional thermal conductivity—42 W/m·K. This makes it perfect for high-power applications like titanium-sapphire lasers. YAG crystals have a thermal conductivity of 14 W/m·K. They balance thermal performance and optical properties well. That’s why they’re widely used in industrial applications.

The host crystal does more than just hold dopant ions in place. It has multiple critical functions. The host material fundamentally affects wavelength output, bandwidth, transition cross-sections, and upper-state lifetimes of laser transitions.

Garnet Structures: Yttrium Aluminum Garnet (YAG) is the most widely used laser crystal family. Garnets like Y₃Al₅O₁₂, Gd₃Ga₅O₁₂ (GGG), and Gd₃Sc₂Al₃O₁₂ (GSGG) have high hardness, chemical inertness, and excellent thermal conductivity. The garnet structure can hold various dopants while keeping optical homogeneity.

Sapphire and Aluminates: Sapphire (Al₂O₃) and related aluminates like YAlO₃ (YALO) have extremely high hardness and thermal conductivity. But they are anisotropic materials. These properties make them great on high-power and ultrafast laser applications.

Vanadates: YVO₄ and GdVO₄ crystals have very high laser cross-sections for Nd³⁺ dopants. This lets them operate efficiently even with low pump powers. But these materials are anisotropic and have lower thermal conductivity than garnets.

Fluorides: Materials like YLiF₄ (YLF) have excellent UV transparency and birefringence properties. Fluoride hosts are especially useful for applications that need high energy storage capacity and specific polarization characteristics.

Tungstates: Monoclinic tungstates (KGW, KYW) and disordered tetragonal tungstates (NGW, NYW) have both high laser cross-sections and large gain bandwidths. These materials are perfect for ytterbium-doped applications and ultrafast laser systems.

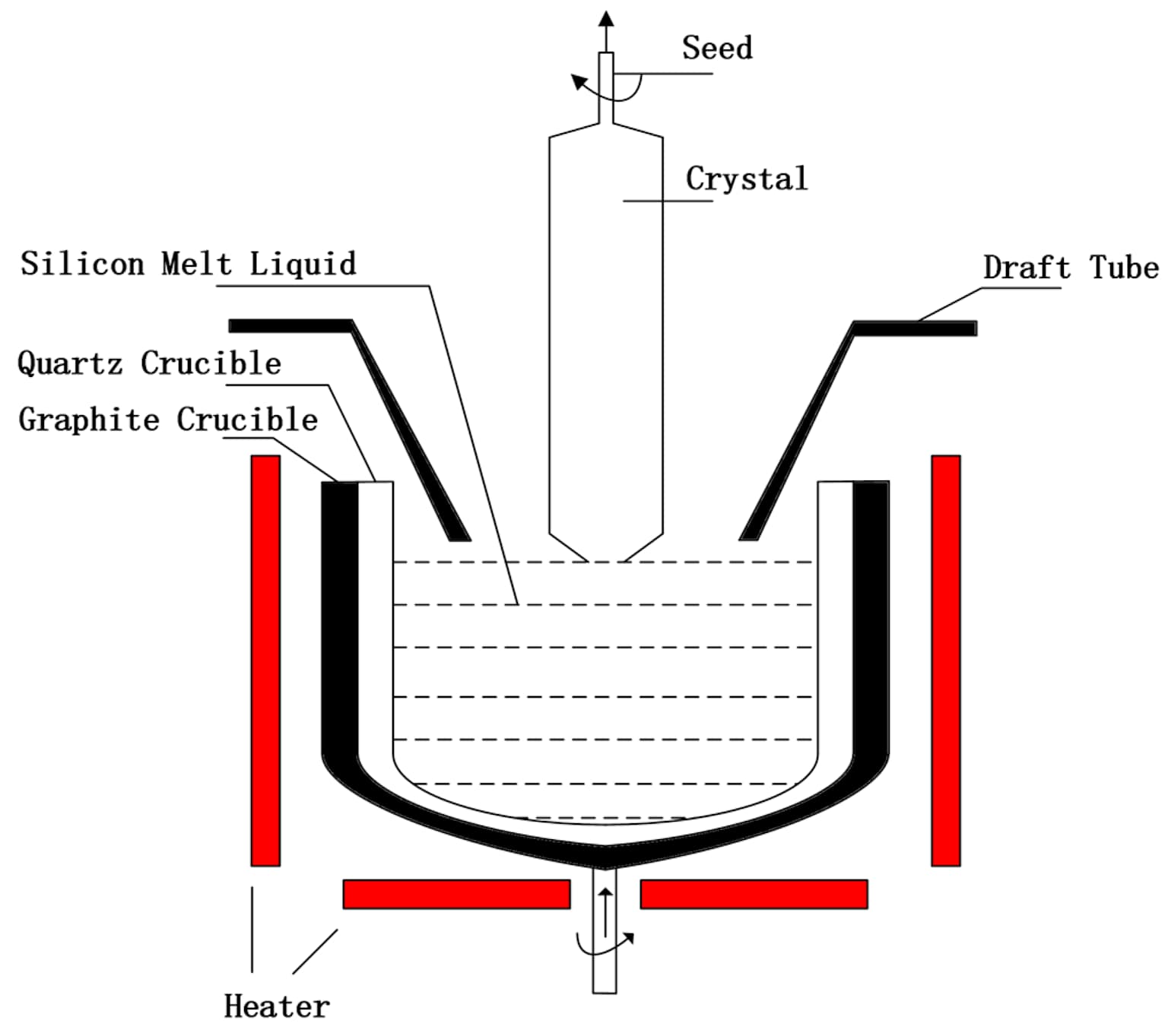

Making high-quality laser crystals needs sophisticated manufacturing processes. You have to control material purity, crystal structure, and optical properties precisely. The manufacturing process directly affects how well the laser crystal performs in the end.

Czochralski Method: This is the most widely used way to grow large, high-quality single crystals. You dip a seed crystal into a molten mixture. Then you slowly pull it out while rotating. This lets atoms from the melt crystallize in the right orientation.

Bridgman-Stockbarger Technique: This method uses controlled solidification of the melt in a container. You move the container through a temperature gradient slowly. It can bring in some impurities from the container walls. But it’s suitable for certain crystal types and shapes.

Float Zone Method: For applications that need ultra-high purity, this process uses electromagnetic induction to melt a section of the crystal. There’s no contact with a container, so contamination is minimal.

Doping Concentration: For rare-earth-doped crystals, typical doping concentrations are 0.1 to 3 atomic percent. The best concentration depends on the application. Higher concentrations let absorption lengths be shorter. But they might cause quenching effects.

Crystal Orientation: Proper crystallographic orientation is key for optimizing optical properties. It also minimizes unwanted effects like thermal birefringence. Different laser designs need specific crystal orientations to work their best.

Material Homogeneity: Dopant ions need to be distributed evenly throughout the crystal. This is crucial for consistent laser performance. If the distribution is uneven, you get spatial variations in gain and unwanted thermal effects.

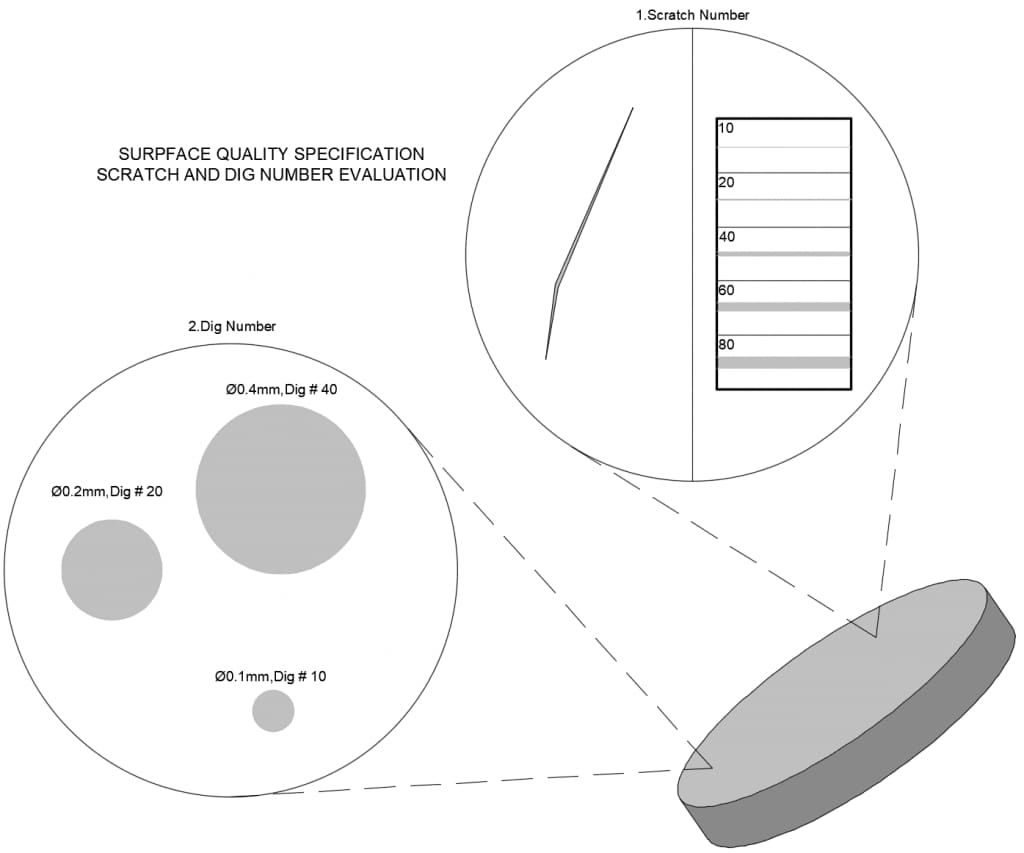

The quality of optical surfaces in laser crystals is super important. It helps achieve high performance and prevents damage. Surface imperfections can start laser-induced damage. They also cause unwanted scattering losses.

Laser crystal surfaces must meet strict standards for flatness, surface roughness, and defect levels. For the most demanding applications—like intra-cavity optics—you need scratch-dig specifications of 10-5. Standard applications might use 40-20. Surface flatness usually needs to be λ/10 or better. This minimizes wavefront distortion and scattering losses. This level of precision needs sophisticated polishing techniques. You also need quality control throughout the manufacturing process.

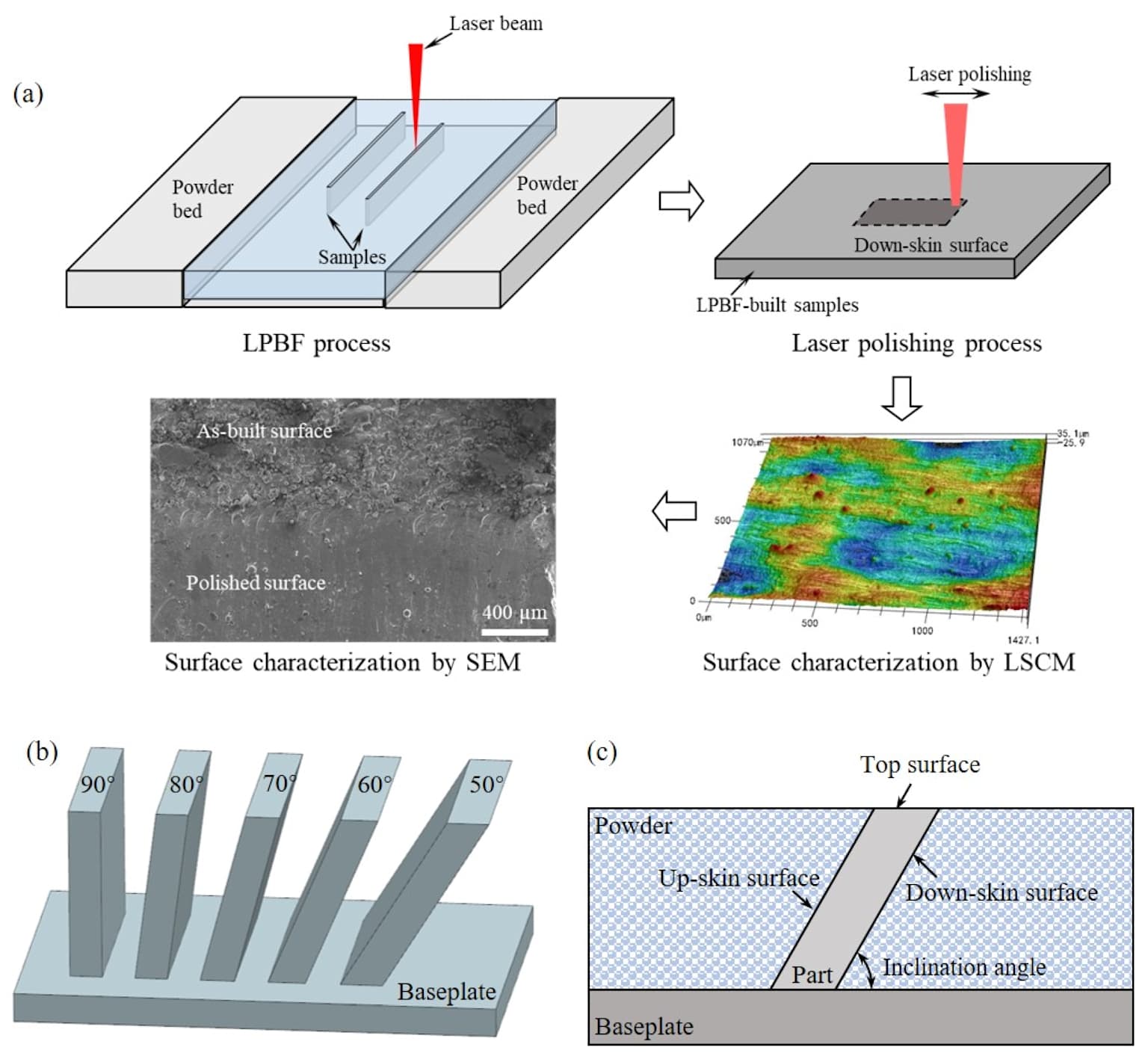

Modern laser crystal manufacturing uses advanced techniques to check surface quality. This ensures it meets specifications. These include scanning electron microscopy (SEM) for microscopic defect analysis. Laser scanning confocal microscopy (LSCM) is used for 3D surface topography measurements.

Laser crystals enable many applications across multiple industries. Each application has specific needs for wavelength, power, beam quality, and reliability.

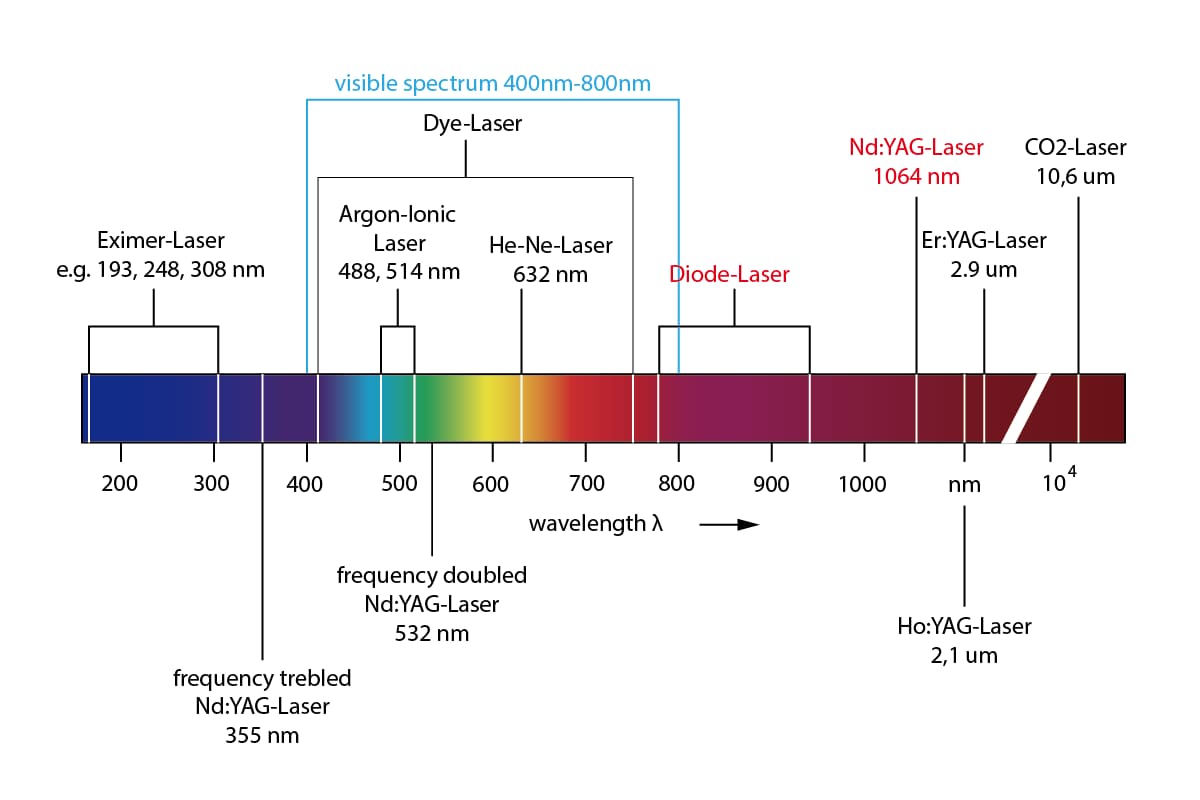

On the medical field, laser crystals power devices used in surgery, dermatology, ophthalmology, and cosmetic treatments. Er:YAG crystals emit at 2.94 μm. They’re especially valuable for medical applications because this wavelength is strongly absorbed by water. This lets you ablate tissue precisely with minimal collateral damage.

Industrial laser systems rely a lot on Nd:YAG and Yb:YAG crystals. They’re used for cutting, welding, marking, and engraving. These crystals have high beam quality and power capabilities. This makes them perfect on precision manufacturing in automotive, electronics, and aerospace industries.

Research applications often need specialized crystals like Ti:sapphire. They’re used on ultrafast laser systems and nonlinear optical experiments. Ti:sapphire has a broad tuning range (650-1100 nm). This makes it invaluable for spectroscopy, microscopy, and fundamental physics research.

The laser crystal industry is still evolving. Researchers are looking into new materials and better manufacturing techniques. Recent developments include ultra-thin optical crystals with better energy efficiency. There are also novel crystal compositions designed for specific applications.

Researchers are looking at new host materials. These have better thermal properties and broader gain bandwidths. Materials like Zn₄B₆O₁₃:Mn²⁺ look promising. They’re good on applications that need low thermal expansion and high thermal conductivity.

Improvements in crystal growth techniques and quality control let us make larger, higher-quality crystals. These have better uniformity and fewer defects. Ceramic laser gain media are also being developed. They’re alternatives to single crystals for certain applications.

Demand for laser technology is increasing across many applications. This is driving growth in the laser crystal market. Key growth drivers include more applications in telecommunications, healthcare, manufacturing.

Laser crystals represent a remarkable convergence of materials science, optics, and precision manufacturing. These sophisticated materials enable wide range of laser applications that have become integral to modern technology and industry. From high - power Nd:YAG crystals used in industrial manufacturing to ultra - precise Ti:sapphire crystals enabling cutting - edge scientific research, each crystal type is carefully engineered for its specific application requirements.

The continued advancement of laser crystal technology, driven by both scientific innovation and market demand, promises even more sophisticated applications in the future. As manufacturing techniques improve and new materials are developed, laser crystals will keep enabling breakthrough technologies that benefit society across numerous fields.

Understanding the principles, properties, and applications of laser crystals provides valuable insight into one of key enabling technologies of modern world. Whether in a surgeon's operating room, a factory production line, or a research laboratory, laser crystals keep demonstrating their importance as heart of solid - state laser technology.

Contact: Jason

Phone: +8613337332946

E-mail: [email protected]

Add: Hangzhou City, Zhejiang Province, China