Laser resonators are fundamental components. They determine oscillation conditions and output characteristics on laser systems. Performance of any laser depends critically on balance between optical gain and various loss mechanisms within resonator cavity. When single - pass gain factor exceeds average single - pass loss factor, laser oscillation can occur. So, understanding and controlling resonator losses is essential for optimal laser design and operation.

Conditions for laser oscillation follow a fundamental principle: small - signal gain coefficient must exceed total loss coefficient for sustained laser emission. This relationship decides threshold conditions for laser operation. It also directly affects output power and beam quality.

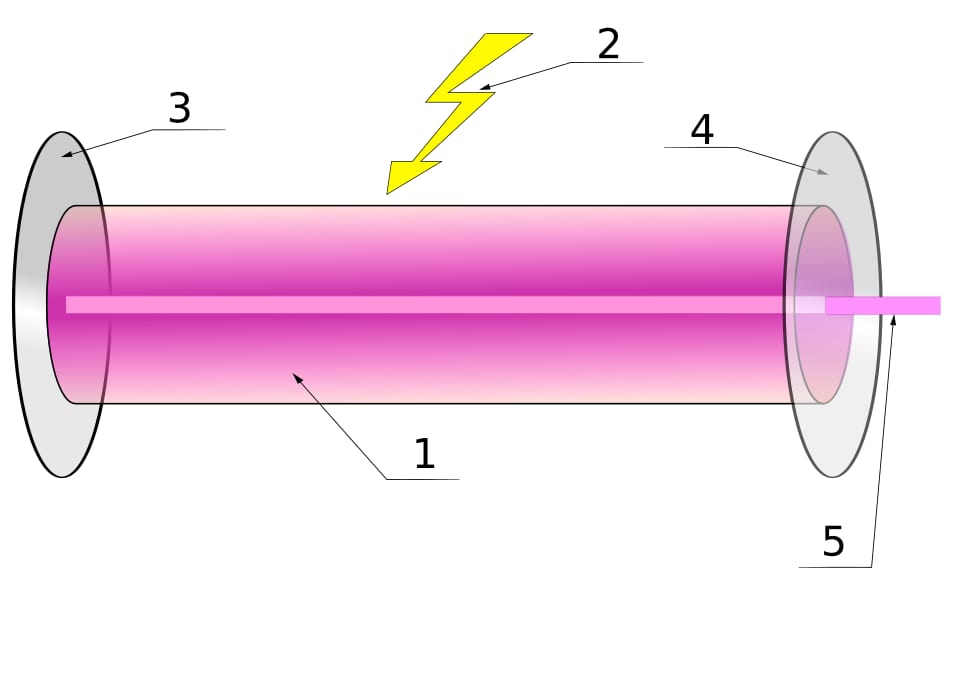

In optical resonators, light circulates in a closed - loop configuration. It bounces between mirrors multiple times before escaping or being absorbed. During this propagation, various physical mechanisms cause optical losses. An resonator without an active gain medium is called a passive cavity. In it, all interactions lead to energy loss instead of amplification.

Magnitude of optical loss during a single round - trip through resonator is measured by average single - pass loss factor. This parameter is key for determining minimum gain required for laser threshold. It also influences overall efficiency of laser system.

Transmission loss is the most significant and controllable loss mechanism in laser resonators. This loss happens because cavity mirrors can’t reflect completely (reflectivity can’t reach 100% in practice).

Primary cause: Finite mirror reflectivity

Output coupling: Intentional transmission through one mirror to extract laser output

Mirror imperfections: Surface quality and coating limitations

An output coupler mirror is designed with partial transmission (usually 1 - 10%) on purpose to extract laser light. High - reflectivity mirrors at the other end of cavity keep reflectivities over 99.9% to reduce parasitic losses.

Transmission loss directly determines:

Threshold pump power: Higher transmission needs more pump energy

Output power: Optimal transmission balances threshold and extraction efficiency

Slope efficiency: Affects conversion of pump power to laser output

Geometric deflection loss occurs when light rays deviate from ideal propagation path and escape through sides of resonator cavity.

Mirror misalignment: Non - parallel mirror surfaces

Beam divergence: Natural spreading of laser beam

Mechanical instability: Vibrations and thermal effects

In an ideal resonator with perfectly parallel mirrors, only light rays perpendicular to mirror surfaces keep stable circulation. Any angular deviation makes them drift toward cavity edges gradually. Finally, light escapes the resonator.

Precise alignment: Use high - stability mirror mounts

Active stabilization: Feedback systems to maintain alignment

Mechanical isolation: Vibration dampening and temperature control

Diffraction loss is an inevitable result of light’s wave nature and finite size of cavity mirrors.

According to wave optics, light propagation in a resonator involves diffraction at each mirror surface. Since mirrors have finite apertures, an small fraction of light diffracts beyond mirror edges during each reflection. This causes cumulative losses.

Cavity length: Longer cavities have higher diffraction losses

Laser wavelength: Shorter wavelengths diffract more severely

Mirror size: Larger mirrors reduce edge diffraction effects

Beam profile: Gaussian beam characteristics influence diffraction patterns

For well - designed laser cavities, diffraction losses are usually kept at 10 - 100 parts per million (ppm). So, they are negligible compared to other loss mechanisms.

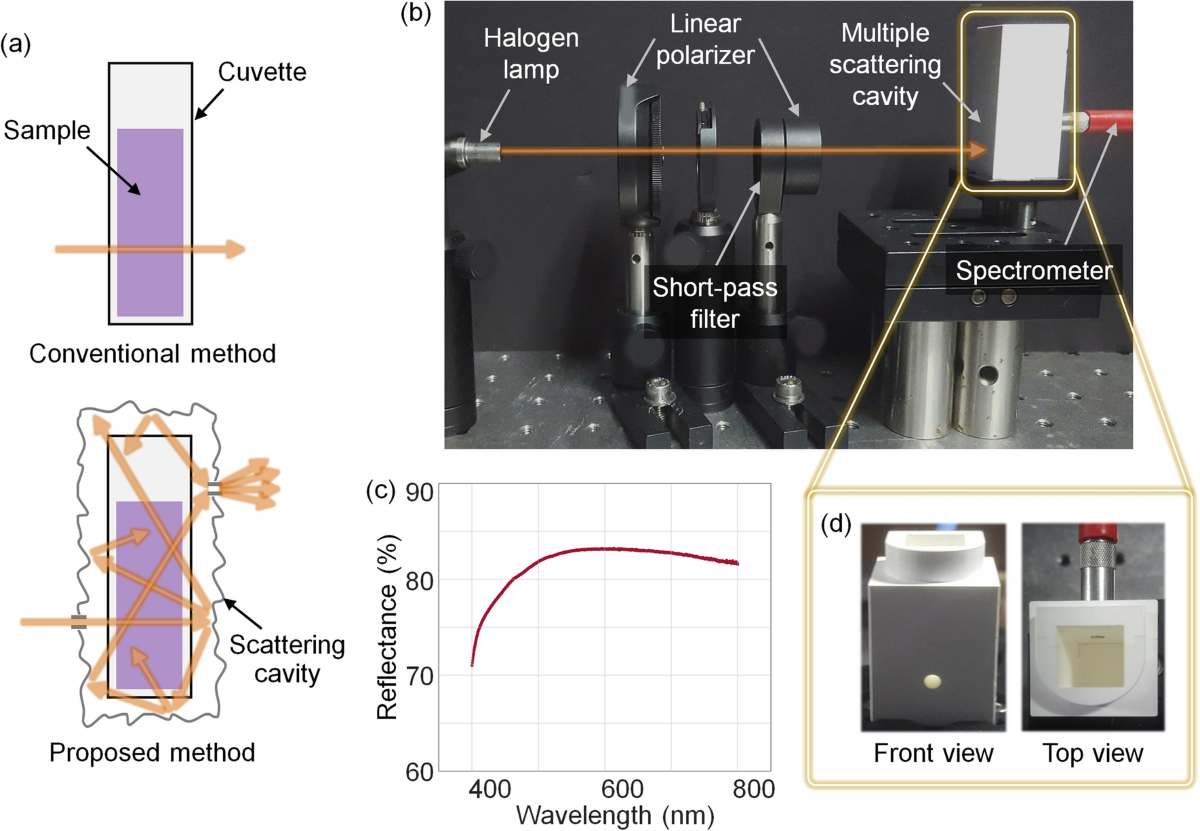

Scattering and absorption losses come from interaction of light with gain medium and other optical components within resonator.

Bulk absorption: Energy converts to heat within gain medium

Surface scattering: Roughness and imperfections on optical surfaces

Volumetric scattering: Inhomogeneities in optical materials

Contamination: Dust particles and surface deposits

Magnitude of these losses varies a lot with:

Wavelength: Material absorption bands affect different laser lines

Crystal quality: Defect density in solid - state gain media

Surface preparation: Polishing quality and cleanliness

Temperature: Thermal effects on material properties

Accessory component loss includes additional losses from optical elements inserted into resonator for specific functionalities.

Q - switches: For pulsed laser operation

Fabry - Pérot etalons: For wavelength selection

Birefringent filters: For polarization control

Frequency - doubling crystals: For harmonic generation

Apertures and diaphragms: For beam shaping

Each component causes losses through:

Surface reflections: Fresnel losses at interfaces

Bulk absorption: Material - specific absorption

Scattering: Surface roughness and bulk inhomogeneities

Insertion losses: Misalignment and coupling efficiency

Cumulative effect of multiple components can affect laser performance greatly. Each element usually adds 1 - 20% loss.

Total average single - pass loss factor of a resonator is found by combining all individual loss contributions:

Total Loss = Transmission Loss + Geometric Loss + Diffraction Loss + Material Loss + Accessory Loss

Each loss type can be analyzed independently. This allows systematic optimization of individual components while keeping overall system performance.

High - Priority Controls:

Transmission optimization: Balance between threshold and output efficiency

Alignment precision: Reduce geometric deflection losses

Component selection: Choose low - loss materials and coatings

Medium - Priority Controls:

Surface quality: Improve polishing and cleaning procedures

Beam sizing: Optimize mode matching to cavity geometry

Environmental stability: Control temperature and vibration

Design Considerations:

Cavity length: Balance between beam quality and loss minimization

Mirror selection: Optimize reflectivity and surface quality

Component minimization: Reduce number of intracavity elements

The five types of losses in laser resonators are distinct physical mechanisms with different sources, magnitudes, and control methods. By understanding each contribution and using appropriate control strategies, laser designers can achieve optimal performance for specific applications while ensuring system reliability and efficiency.

Modern laser systems benefit from careful analysis of these loss mechanisms. This leads to better designs that maximize output power, maintain beam quality, and ensure long - term stability. The continuous development of low - loss optical components and precision manufacturing techniques enables creation of more and more sophisticated laser systems for scientific, industrial, and technological applications.

Contact: Jason

Phone: +8613337332946

E-mail: [email protected]

Add: Hangzhou City, Zhejiang Province, China