Optical fiber cable technology revolutionizes modern telecommunications. It enables high - speed data transmission across vast distances with unprecedented reliability an bandwidth capacity. As digital demands keep surging globally, understanding fiber optic infrastructure grows crucial for network professionals, engineers, an decision - makers planning future - ready communication systems.

An optical fiber cable consists of one or multiple optical fibers enclosed within protective layers. These layers safeguard the delicate glass cores from environmental factors, mechanical stress, an electromagnetic interference. Unlike traditional copper - based communication systems, fiber optic cables transmit data using light signals. They achieve transmission speeds approaching 99.7% of the speed of light.

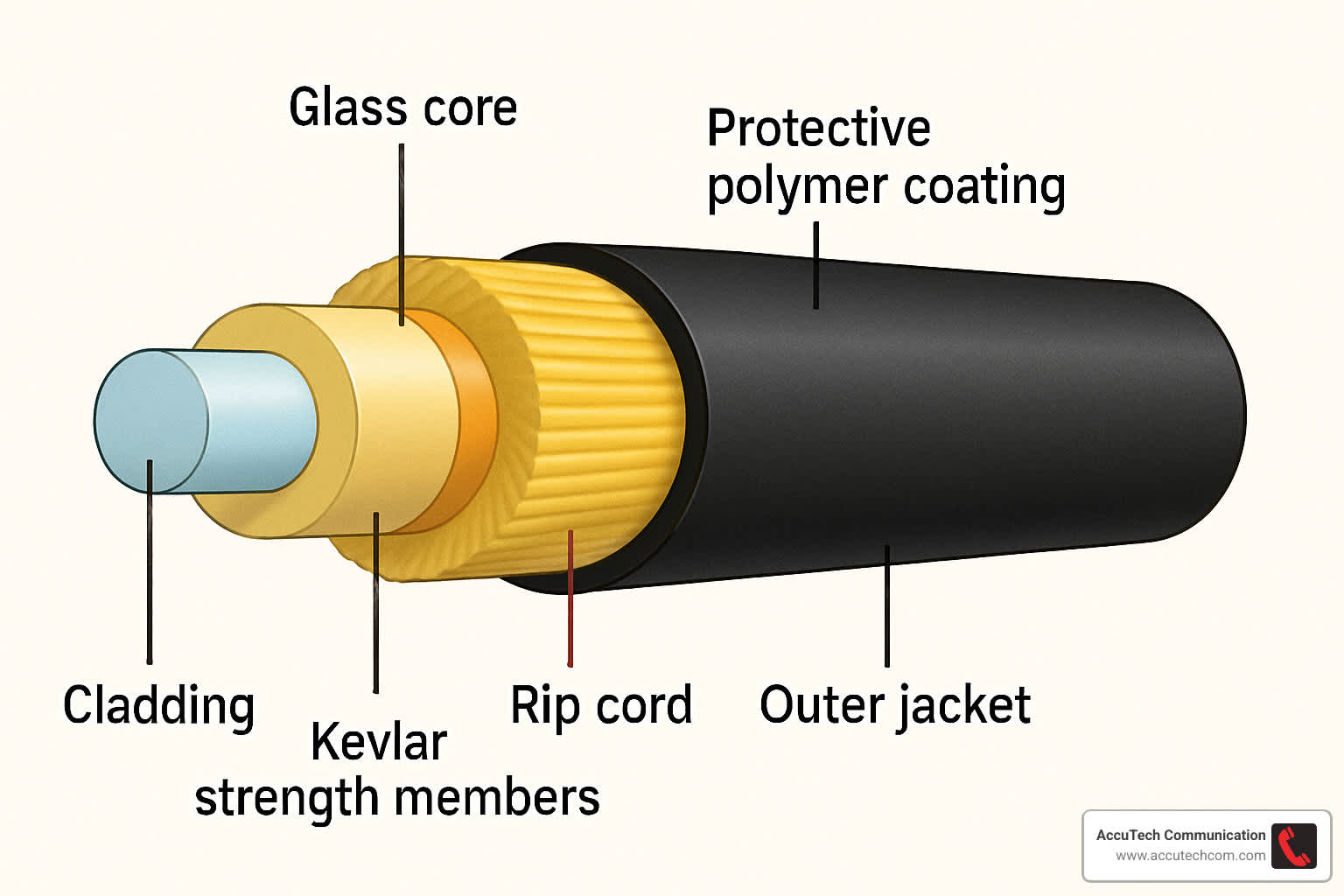

The fundamental structure of optical fiber cable has several critical layers. Each layer serves specific protective an functional purposes. The innermost glass core carries light signals. It typically measures between 8 - 62.5 micrometers in diameter depending on the fiber type. Surrounding the core, the cladding layer maintains total internal reflection. It has a lower refractive index than the core material, ensuring light signals remain contained within the transmission path. The protective coating layers shield the fragile glass components from moisture, physical damage, an microbending losses. Most fiber cables use strength members made from aramid yarn (like Kevlar) or steel wire strands. These provide tensile strength during installation an operation. The outermost jacket material varies based on application requirements. Options include PVC, polyethylene (PE), or low - smoke zero - halogen (LSZH) compounds for enhanced fire safety.

The telecommunications industry mainly uses two fundamental fiber cable categories. Each is optimized for specific transmission requirements.

Single - mode fiber (SMF) has an extremely narrow core diameter of 8 - 10 micrometers. It allows only one light mode to propagate. This design minimizes modal dispersion, enabling long - distance transmission with minimal signal degradation. SMF cables typically support distances exceeding 80 kilometers an data rates from 10 Gbps to 400 Gbps. They are ideal for backbone networks an metropolitan area connections.

Multimode fiber (MMF) has larger core diameters of 50 or 62.5 micrometers. It supports multiple light paths simultaneously. While MMF provides higher data capacity over shorter distances, it has greater modal dispersion. Modern multimode classifications include OM1, OM2, OM3, OM4, an OM5 categories. OM4 an OM5 fibers support 40 - 100 Gbps transmission over distances up to 550 meters.

The photonics bandwidth concepts are fundamental to understanding how different fiber types achieve their performance characteristics.

Tight - buffered fiber cables feature 900 - micrometer buffered fibers surrounded by protective coatings an strength members. The construction uses a dual - layer protective system: an inner plastic coating an an outer waterproof acrylate layer that prevents moisture infiltration. This design provides superior mechanical protection an flexibility. It makes tight - buffered cables ideal for indoor applications, data centers, an building backbone installations. The buffering material directly contacts the fiber, creating a robust structure that withstands repeated handling an moderate environmental stresses. Tight - buffered cables typically accommodate 2 - 144 fibers an offer easier termination procedures compared to loose - tube alternatives. However, this construction method results in higher costs an larger cable diameters relative to loose - tube designs.

Loose - tube fiber optic cables house multiple 250 - micrometer coated fibers within semi - rigid protective tubes. The fibers move freely within gel - filled or dry tubes. This allows thermal expansion an contraction without stress transfer to the glass components. Additional protective layers include water - blocking materials, strength members, an outer jackets designed for harsh environmental conditions. This construction excels in outdoor installations, direct burial applications, an long - distance trunk lines where environmental protection takes priority over handling convenience. Loose - tube cables support higher fiber counts (up to 288+ fibers) in smaller overall diameters compared to tight - buffered alternatives. However, termination procedures need fan - out kits an additional installation time.

Modern fiber optic infrastructure uses various specialized cable designs tailored for specific applications. Ribbon cables arrange multiple fibers side - by - side in flat ribbon formations. They typically contain 12 fibers per ribbon with multiple ribbons stacked for high - density installations. Duplex cables combine two single fibers for bidirectional communication. They are commonly used in point - to - point connections. Armored fiber cables include additional metallic sheathing for enhanced mechanical protection. They are suitable for direct burial, overhead installations, an industrial environments subject to physical stress. Submarine cables have specialized designs. They can withstand immersion in fresh or saltwater environments while protecting against anchors, fishing equipment, an extreme hydrostatic pressures.

The National Electrical Code (NEC) sets comprehensive fire safety classifications for optical fiber cables installed in buildings. These classifications ensure proper cable selection based on installation environment an fire propagation requirements. OFNP (Optical Fiber Nonconductive Plenum) an OFCP (Optical Fiber Conductive Plenum) represent the highest fire - resistance ratings. These cables resist flame spread an minimize smoke generation when exposed to fire. They are suitable for air - handling spaces, ventilation ducts, an plenum areas. OFNR (Optical Fiber Nonconductive Riser) an OFCR (Optical Fiber Conductive Riser) cables prevent fire propagation between building floors. While offering lower fire resistance than plenum - rated cables, riser classifications provide adequate protection for vertical installations an multi - floor applications. OFNG/OFCG (General Purpose) an OFN/OFC (Commercial Grade) classifications suit horizontal runs an general building installations with reduced fire - resistance requirements.

The "C" designation indicates conductive cables containing metallic components such as strength members, armor, or moisture barriers. Conversely, "N" classifications identify completely non - conductive cables containing only dielectric materials. This distinction affects installation requirements an compatibility with existing building systems.

The International Telecommunication Union Telecommunication Standardization Sector (ITU - T) has established comprehensive standards for optical fiber performance. ITU - T G.651 defines multimode graded - index fiber characteristics. G.651.1 specifies enhanced multimode fiber for optical access networks. ITU - T G.652 through G.657 classifications cover various single - mode fiber types optimized for different applications. G.652 remains the most widely deployed single - mode fiber for long - distance an metropolitan networks. G.657 bend - insensitive fibers enable tighter installation radii without performance degradation.

Critical fiber specifications include attenuation coefficients measured in decibels per kilometer (dB/km). Modern single - mode fibers achieve attenuation levels below 0.5 dB/km at 1310nm an 1550nm wavelengths. Multimode fibers typically show 2.3 - 3.5 dB/km attenuation at 850nm. Bandwidth specifications define the maximum data carrying capacity over specific distances. Single - mode fibers support virtually unlimited bandwidth over long distances. Multimode bandwidth varies by category: OM3 fibers provide 2000 MHz·km at 850nm, OM4 achieves 4700 MHz·km, an OM5 extends capabilities across broader wavelength ranges.

Fiber optic cables serve as the backbone for modern telecommunications networks. They support everything from internet connectivity to mobile backhaul systems. The global fiber optic cable market, valued at approximately $13.9 billion in 2025, is projected to reach $34.5 billion by 2034. This growth is driven by 5G deployments an data center expansion. Data centers are one of the fastest - growing application segments. They need high - density fiber connectivity for server - to - server communication an external network connections. Modern hyperscale facilities demand thousands of fiber connections supporting 100G an 400G transmission rates.

Beyond telecommunications, fiber optic cables enable numerous industrial applications. These include medical imaging, military communications, aerospace systems, an manufacturing automation. Fiber lasers used in automotive manufacturing, materials processing, an precision cutting need specialized fiber delivery systems capable of handling high optical power levels.

For industrial fiber laser applications, our Fiber Laser Marking Machine offers precision marking capabilities with wavelengths optimized for fiber optic systems. These systems utilize the same fiber optic principles discussed in this article, providing reliable performance for marking cables, components, and related infrastructure.

Lighting and decorative applications use fiber optics for architectural illumination, entertainment systems, and safety lighting in hazardous environments. These applications often use fiber bundles containing numerous smaller fibers arranged in coherent or incoherent configurations depending on image transmission requirements.

Understanding stimulated emission principles is crucial for optimizing fiber laser performance in industrial applications.

Advanced fiber technologies are enabling next - generation applications. These include quantum communication systems, hollow - core fiber networks, an multicore fiber installations. Hollow - core fibers reduce signal propagation time by allowing light to travel through air rather than glass. They achieve latency reductions of up to 30% compared to conventional fibers. 5G and 6G network deployments need extensive fiber infrastructure to support small - cell backhaul an fronthaul connections. Each 5G base station typically needs dedicated fiber connections, multiplying cable requirements by 3 - 5 times compared to legacy 4G installations.

The development of ultrashort pulse generation technologies continues to expand fiber optic capabilities for next-generation applications.

Successful fiber optic installations need adherence to strict handling procedures to prevent damage during deployment. Minimum bend radius specifications must be maintained throughout installation an operation—typically 10 - 20 times the cable diameter depending on cable type.

Cable pulling tension must stay below manufacturer specifications to prevent strength member failure or fiber breakage. Professional installations use specialized pulling grips and monitoring equipment to ensure tension limits are not exceeded. Figure-8 deployment patterns help prevent cable twisting during long cable runs.

For cable identification and marking during installation, our NM720 White Inkjet Printing Machine provides high-contrast marking on dark cable surfaces including PVC, PE, LSZH, and PP materials commonly used in fiber optic cable construction.

Outdoor fiber installations must account for temperature variations, moisture protection, an ultraviolet radiation exposure. Gel - filled loose - tube cables provide enhanced moisture protection but need specialized termination procedures an clean - up processes. Fire safety regulations require proper cable selection based on installation environment. Plenum - rated cables must be used in air - handling spaces, while riser - rated cables suffice for vertical runs between floors. Indoor/outdoor transition points need careful sealing to prevent moisture infiltration.

Optical fiber cable technology is the foundation of modern digital communication infrastructure. It enables the high-speed, high-capacity networks essential for today's connected world. From basic single-mode and multimode designs to specialized configurations for harsh environments, fiber optic cables provide unmatched performance characteristics. These include enormous bandwidth capacity, electromagnetic immunity, and long-term reliability.

Understanding proper cable selection, installation techniques, and safety classifications ensures optimal network performance and regulatory compliance. As emerging technologies like hollow-core fibers, quantum communications, and 6G networks keep advancing, fiber optic infrastructure will remain central to enabling next-generation applications and services.

The continued expansion of global fiber networks, driven by increasing data demands and government infrastructure initiatives, positions optical fiber cables as a critical technology for bridging the digital divide and supporting economic development worldwide. Investment in quality fiber optic infrastructure today provides the foundation for decades of future technological advancement and connectivity growth.

Featured Products for Fiber Optic Applications:

Fiber Laser Marking Machine - Professional laser marking systems utilizing fiber optic delivery for precision marking of cables and components

NM720 White Inkjet Printing Machine - High-contrast marking solution for fiber optic cable identification and labeling

Contact: Jason | Phone: +8613337332946 | Email: [email protected]

Contact: Jason

Phone: +8613337332946

E-mail: [email protected]

Add: Hangzhou City, Zhejiang Province, China