Yttrium lithium fluoride (YLF) lasers are an sophisticated type of solid-state laser. They’ve become important on many fields—from precise medical procedures to advanced scientific research. These lasers use specialized crystalline host materials doped with rare-earth ions. This gives them unique optical and thermal traits that set them apart from traditional lasers. The development of YLF laser technology has opened new doors for uses needing exceptional beam quality, precise wavelength control, and top-notch thermal management.

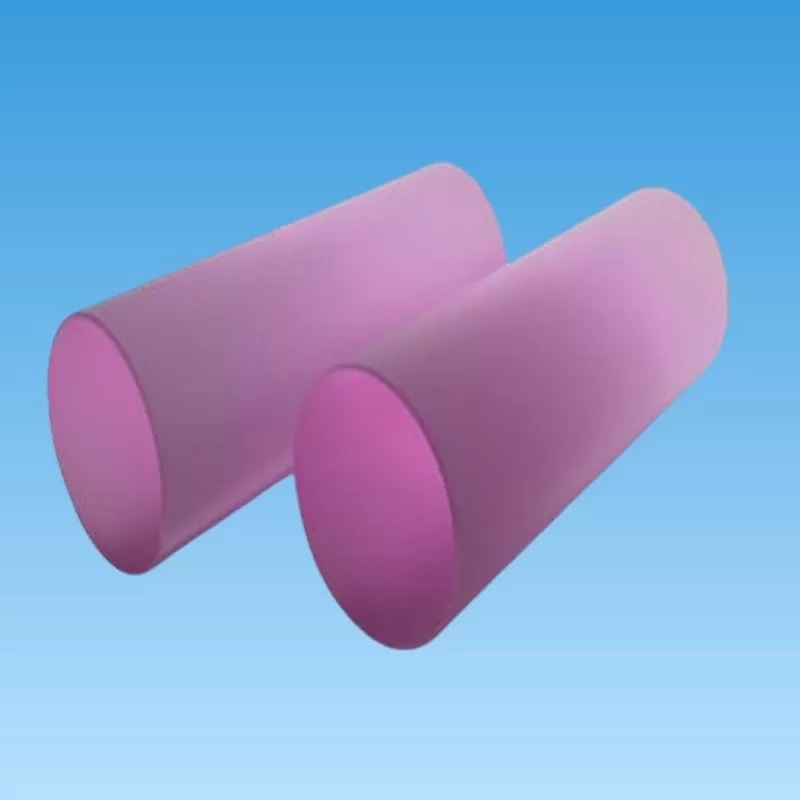

Yttrium lithium fluoride (chemical formula LiYF₄) is the main host material for rare-earth-doped laser crystals. This fluoride crystallizes in an tetragonal structure (space group I41/a). It has lattice parameters: a=5.16 Å, c=10.85 Å. It has a density of 3.99 g/cm³. It stays structurally stable until its melting point—819°C.

The tetragonal structure of YLF is perfect for adding rare-earth ions. Yttrium and laser-active rare-earth elements have similar ionic radii. This lets them substitute without messing up the lattice. You can dope YLF with neodymium, ytterbium, erbium, thulium, holmium, and praseodymium. Each gives distinct spectroscopic properties and laser performance.

Neodymium-doped YLF (Nd:YLF) is the most common type. But other doping methods show big potential for specific uses. Thulium-doped YLF (Tm:YLF) works great on the 2-micrometer spectral range. This makes it perfect for an medical uses where high water absorption helps. Holmium-doped YLF (Ho:YLF) can operate at room temperature with high power. This fixes the old problem of needing cryogenic cooling.

YLF crystals have inherent birefringence. This is one of their biggest advantages over isotropic laser materials. This natural optical anisotropy gets rid of thermally induced depolarization losses. These losses are an common problem in high-power lasers. YLF is positively uniaxial. This keeps polarization consistent even when thermal conditions change. It helps improve beam quality and system stability.

Nd:YLF’s emission changes with polarization. It shows distinct spectral lines with an different intensities and wavelengths. The π-polarized emission at 1047 nm is the strongest. The σ-polarized line at 1053 nm is weaker, but it matches neodymium glass amplifiers perfectly. There are also transitions at 1313 nm (σ-polarization) and 1321 nm (π-polarization). These let you generate frequency-doubled red light for special uses.

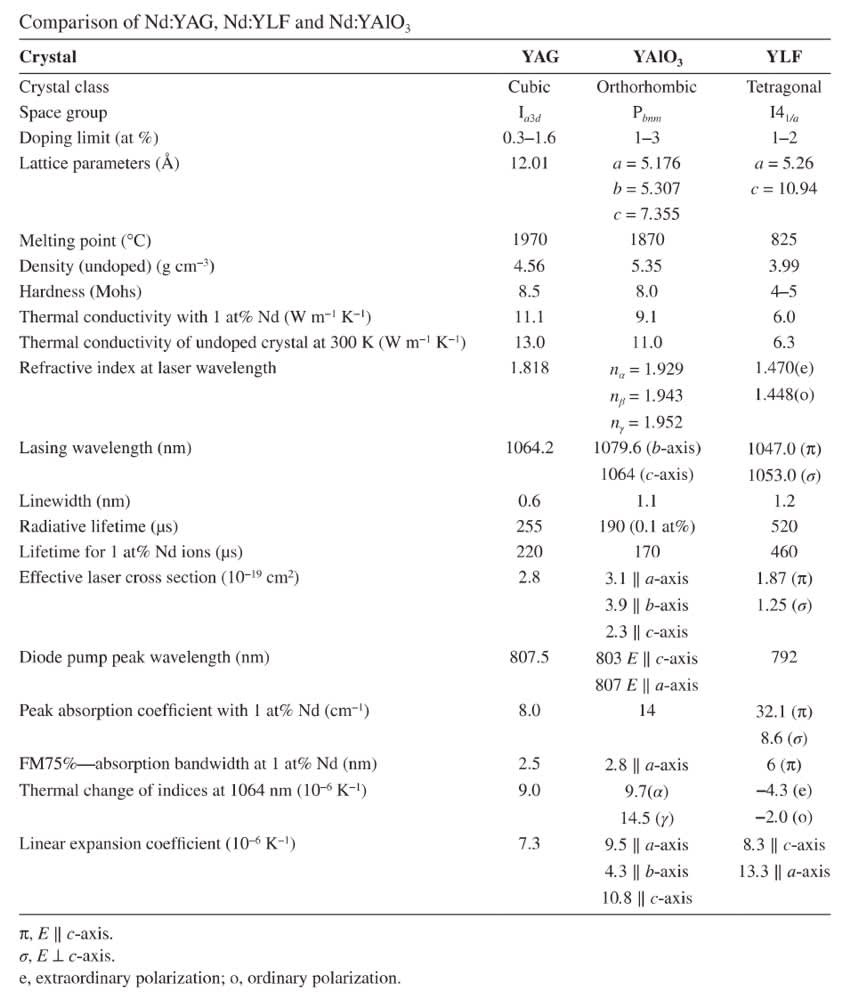

Nd:YLF has a fluorescence lifetime of about 485 microseconds. That’s much longer than Nd:YAG’s 230 microseconds. This lets it store more energy—great for Q-switched lasers. This longer upper-state lifetime lets diode-pumped systems produce higher pulse energies. It works well at repetition rates under an few kilohertz.

The stimulated emission cross-sections for Nd:YLF change with polarization and wavelength. At 1047 nm, it’s 1.8×10⁻²⁰ cm². At 1053 nm, it’s 1.2×10⁻²⁰ cm². These cross-sections are lower than Nd:YAG’s. But they help YLF systems have better beam quality.

YLF crystals have negative thermo-optic coefficients (dn/dT). This makes their thermal lens traits very different from traditional laser materials. This creates an defocusing thermal lens. You can partially fix it with the focusing effect of thermally induced end-face bulging—if the design is right. The thermo-optic coefficients for YLF are -4.3×10⁻⁶ K⁻¹ for E∥c polarization and -2.0×10⁻⁶ K⁻¹ for E⊥c polarization.

Recent studies show complex polarization-dependent thermal lensing in YLF crystals. This is especially true at cryogenic temperatures. For E∥a polarized light, thermal lensing is strong and converging. For E∥c, it’s weaker with axis-dependent sign changes. This asymmetry lets you optimize thermal lensing in high-power laser designs.

YLF has anisotropic thermal conductivity. Along the a-axis, it’s 5.3 W/(m·K). Along the c-axis, it’s 7.2 W/(m·K). These values are lower than Nd:YAG’s (about 14 W/(m·K)). But the negative thermo-optic coefficient reduces overall thermal distortion. This improves beam quality. The thermal expansion coefficients are also anisotropic: 14.3×10⁻⁶ K⁻¹ for the a-axis, 8.4×10⁻⁶ K⁻¹ for the c-axis.

Comparing Nd:YLF and Nd:YAG shows their strengths and weaknesses. This helps choose the right material for specific uses. YLF has better beam quality. That’s because it has less thermal distortion—even though its thermal conductivity is lower. It’s perfect for uses that need great spatial beam traits.

YLF’s longer fluorescence lifetime (485 μs vs. 230 μs for YAG) is a big plus for Q-switched lasers. It lets you get higher pulse energies at low repetition rates. But YLF is less durable than YAG. It’s more brittle, so it can’t handle as much power.

The 1053 nm emission line of YLF is unique. It matches the gain peak of Nd:glass amplifiers perfectly. This makes YLF ideal for high-energy laser systems used in inertial confinement fusion research.

YLF crystals are less mechanically durable than YAG. Their Mohs hardness is 4-5, while YAG’s is 8-9. This means you have to handle them carefully during fabrication and installation. YLF also dissolves slightly in water. You need to protect it from moisture during long-term use.

YLF crystals absorb light well on the 792-810 nm range. Peak absorption is usually around 797 nm. This makes diode pumping efficient. This absorption band matches well with common high-power diode lasers. It makes laser systems smaller and more efficient. The absorption bandwidth is about 1.5 nm (FWHM). You need to stabilize the pump diode wavelength for best performance.

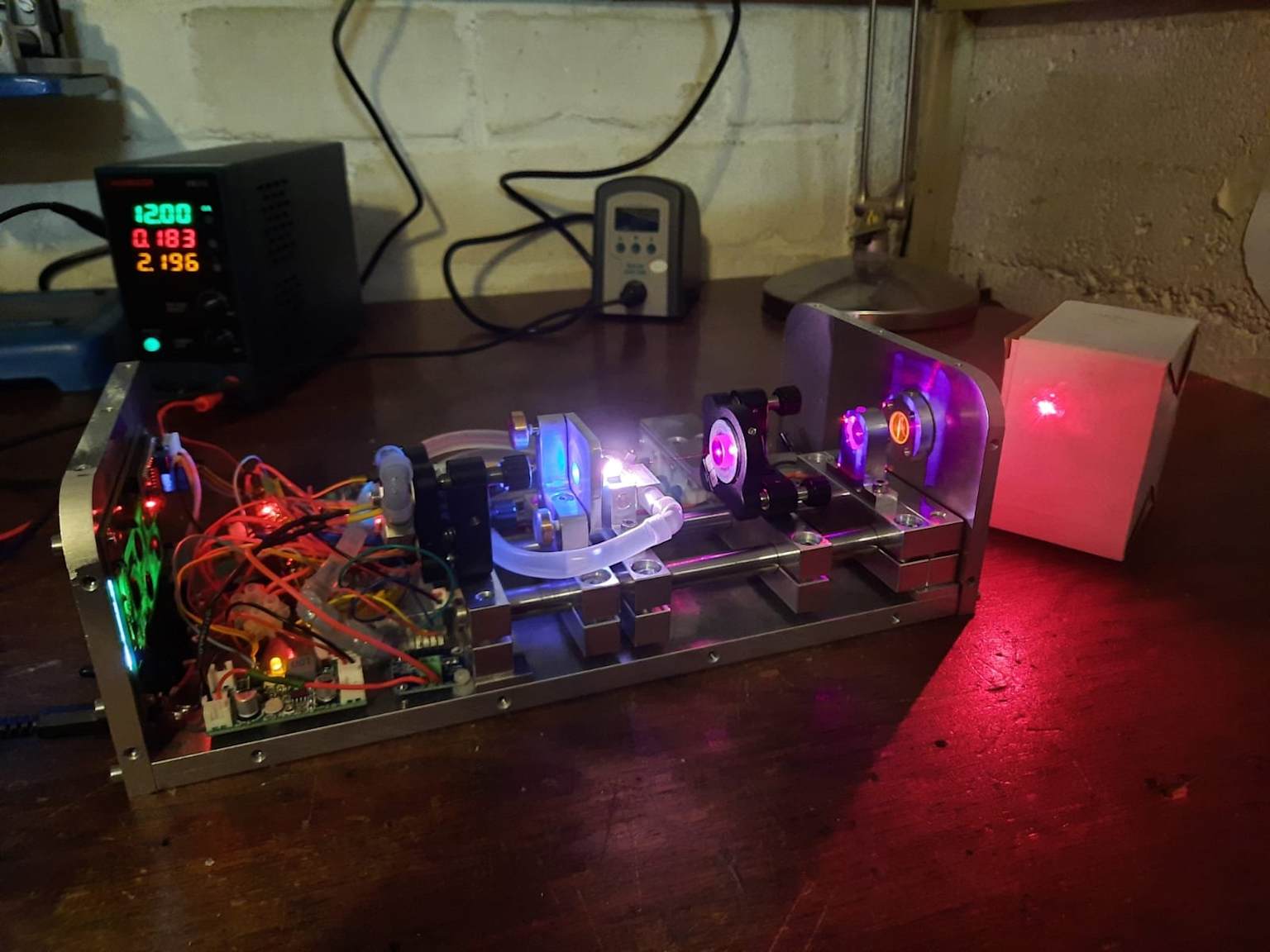

Modern diode-pumped YLF systems work really well. Some can produce multi-joule pulse energies at kilohertz repetition rates. Quasi-continuous-wave (QCW) diode arrays let you scale to high average powers. They keep the great beam quality that YLF is known for.

YLF crystals are very transparent to UV light. This is a big advantage for xenon flashlamp pumping. They let you use the broadband emission from xenon sources efficiently. YLF has a higher UV-induced damage threshold than other fluoride crystals. This makes it perfect for high-energy flashlamp-pumped systems.

YLF lasers are widely used in medical procedures. They need high precision and little thermal damage. Tm:YLF systems emit 2-micrometer light. This absorbs water perfectly for surgery. It lets doctors ablate tissue precisely with little damage to surrounding areas. Dermatological treatments, dental work, and eye surgeries all benefit from YLF’s great beam quality and controllable pulses.

YLF lasers have naturally polarized output. This means you don’t need extra polarization control parts. It simplifies medical laser designs. Combined with great beam quality, it lets you focus more precisely and treat smaller areas.

Precision manufacturing uses YLF lasers for tasks needing great beam quality and precise wavelength control. Micromachining, precision cutting, and marking all benefit from YLF’s stable, low-noise output. You can generate frequency-doubled output to process materials that absorb specific wavelengths.

YLF lasers are key parts of advanced scientific research. They’re often used as pump sources for Ti:Sapphire amplifier systems. The 1053 nm output pumps ultrafast Ti:Sapphire chirped-pulse amplification systems. These are used in high-field physics research. Military and defense uses YLF systems for laser ranging, LIDAR, and optical countermeasures. They benefit from eye-safe wavelengths and long-range capability.

High-energy physics facilities use YLF-based seed lasers and preamplifiers for large-scale glass laser systems. These are used in inertial confinement fusion experiments. The spectral match between YLF emission and glass amplifier gain lets you extract energy efficiently from multi-stage amplifier chains.

Crystal growth techniques are getting better—like micro-pulling-down and improved atmospheric control. This keeps making YLF crystals better and more available. Researchers are focusing on reducing defects, improving optical homogeneity, and making larger crystals for high-power uses. Composite crystal structures (like Ho:YLF bonded with undoped YLF caps) are a new way to make YLF more mechanically robust.

Cryogenic YLF laser systems are opening new doors for high-power uses. Traditional thermal limits are no longer a problem. Room-temperature operation of previously cryogenic-only systems (like Ho:YLF thin-disk lasers) is a big step forward. Combining YLF with advanced beam shaping and adaptive optics is expanding its uses even more.

Yttrium lithium fluoride laser technology is mature but still evolving. It meets specific performance needs that traditional lasers don’t. YLF has a unique mix of traits: birefringence, negative thermo-optic coefficients, long fluorescence lifetime, and special spectral characteristics. This makes it the best choice for uses that need great beam quality, precise wavelength control, and specialized thermal management.

YLF crystals have some limitations—like lower mechanical durability and power handling compared to YAG. But their advantages keep driving innovation in laser design and applications. Advances in crystal growth, system integration, and application-specific optimization mean YLF will stay relevant for next-generation photonic systems. It will be used in medical, industrial, scientific, and defense sectors for years to come. As demand for high-precision, high-quality lasers grows, YLF technology is ready to meet the challenge.

Contact: Jason

Phone: +8613337332946

E-mail: [email protected]

Add: Hangzhou City, Zhejiang Province, China