Hello, I’m an engineer behind Nano Mark. Today I want take you on a journey through three primary laser marking technologies I use on my workshop. Laser marking has become essential for everything from product serialization to decorative engraving. Understanding differences between these methods will help you choose right approach for your project. In this post, I'll share my firsthand experiences with mask - mode marking, array (dot - matrix) marking, and galvanometer scanning marking—covering how they work, their strengths and weaknesses, and when I reach for each in my own work.

Mask - mode marking (also called projection marking) is conceptually similar with slide projection. You first create a mask—a thin plate etched with your desired pattern of numbers, text, barcodes, or images. An collimated laser beam is expanded to uniformly illuminate the mask; only laser light passing through etched areas makes it to imaging lens, which focuses that pattern onto your workpiece. The high - energy pulses vaporize or chemically alter surface wherever the beam is focused, leaving a crisp mark.

Complete - pattern pulses: Each laser pulse prints entire pattern at once, making it fast for repetitive, identical marks.

High contrast: The rapid heating causes clear surface changes—ideal for serial numbers or logos.

Inline integration: Mask - mode modules can slot directly onto production lines for high - volume runs.

Low flexibility: Every time you need a new pattern, you must fabricate a new mask—a costly and time - consuming process.

Wasted energy: Much of the beam is blocked by the mask, reducing overall efficiency.

Limited complexity: Intricate or variable data (like unique IDs per part) is impractical.

I find mask - mode marking well - suited for very high - volume, identical - part production—when cost of making a mask can be amortized over thousands of pieces.

Array marking uses a cluster of small RF - excited CO₂ lasers or fiber - optics to generate many simultaneous pulses. These beams pass through a static mirror assembly and focusing lens to ablate (melt) micro - pits in material’s surface, typically arranged as a 5×7 dot matrix per character. Each character or graphic is simply a grid of these uniform pits.

High throughput: Capable of marking up to 6,000 characters per second, making it ideal for fast, inline coding.

No moving parts: With a fixed array, reliability is excellent and maintenance is minimal.

Predictable pattern: Uniform pit size and depth yield consistent readability for barcodes and basic text.

Limited resolution: The fixed 5×7 grid cannot render fine detail or complex Chinese characters.

Static character set: You’re confined to preconfigured matrix—custom graphics or fonts aren’t supported.

Monochrome output: The pits appear black, so there’s no variation in contrast or shading.

In my shop, I typically reserve array marking for rapid batch coding of simple alphanumeric labels—especially when speed trumps flexibility.

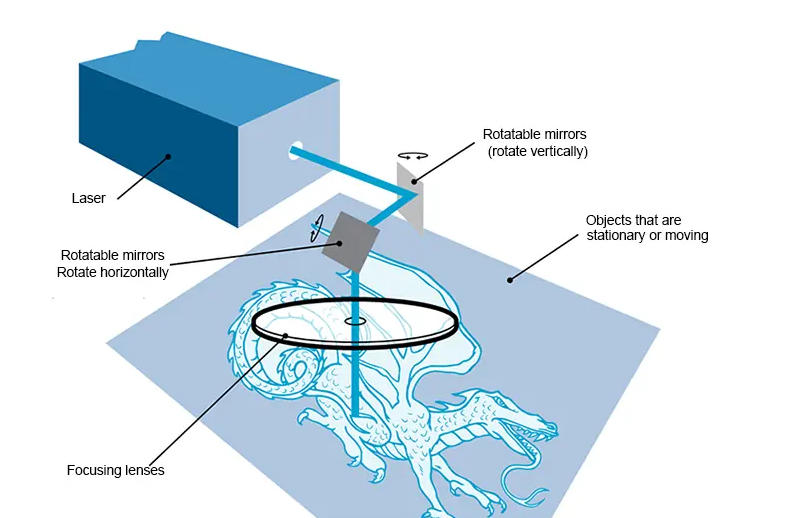

Galvo scanning marking is what I reach for in most custom engraving jobs. A galvanometer system directs laser beam onto two fast - moving mirrors—one for X - axis and one for Y - axis—so that it “draws” your design directly onto surface, much like a pen on paper. The artwork is represented as vector paths, and computer synchronizes mirror angles to trace every line and curve.

Nd:YAG (1.06 μm): Offers continuous output from 10 W up to 120 W—great for metals and hard plastics.

RF - excited CO₂: Also popular, especially for non - metallic substrates.

Excimer (ultraviolet): Minimally heats the material, producing photochemical ablation for ultra - crisp edges—ideal for delicate substrates.

Ultimate flexibility: Any vector graphic, text, or dot - matrix code can be drawn on demand.

Adjustable area and resolution: Scale your artwork up or down without distortion.

High speed and quality: Hundreds of characters per second with precise, distortion - free marks.

Parameter trade - offs: Marking speed, laser power, and spot resolution interact—dialing in optimal settings takes experience.

Thermal effects: With Nd:YAG and CO₂, heat diffusion can create slight “hot edges” if not tuned properly.

Equipment cost: High - precision galvanometer scanners and UV sources carry a premium.

For prototypes, small - batch runs, or intricate engravings—especially where unique data must be applied per part—I rely on galvanometer systems. Their adaptability makes them go - to for everything from QR codes to ornate logos.

For mass production of identical marks, mask - mode offers unbeatable per - piece speed once masks are made.

When you need blistering coding speed for basic alphanumeric runs, array marking delivers.

For custom, high - resolution, or on - the - fly variable data, galvanometer scanning is clear winner.

Each method has its place. In my own projects—ranging from manufacturing PCBs to personalizing gift items—I often combine them: array marking for large batch serialization followed by galvo engraving for decorative logos.

Can I mark any material with all three methods?

Generally, yes—but each laser type interacts differently. Mask - mode and galvo systems with Nd:YAG excel on metals and plastics, while CO₂ lasers (array or galvo) are better for organic or polymeric materials. Excimer lasers are best for fragile or heat - sensitive substrates.

How do I change from one marking method to another on my production line?

Switching methods usually requires swapping out laser head or entire module. Modular laser workstations allow quick changeovers, though aligning optics and calibrating software settings can take up to 30 minutes.

Does mask - mode marking support serialization or variable data?

Not practically. Every unique code means a new mask. For variable or serialized data, galvanometer scanning or dedicated inkjet/thermal transfer is far more efficient.

What maintenance do these systems require?

Mask - mode and array heads need occasional mirror and lens cleaning. Galvo scanners require periodic calibration of mirror alignment and verification of galvanometer response. Laser sources themselves may need maintenance per manufacturer recommendations.

How do I optimize mark contrast and speed on galvanometer systems?

Balance laser power, scan speed, and pulse frequency. Higher power and slower speed deepen marks but risk heat - affected zones. For fine marks, lower power with increased pulse density works best. Always test on scrap material to dial in ideal settings.

Contact: Jason

Phone: +8613337332946

E-mail: [email protected]

Add: Hangzhou City, Zhejiang Province, China