Q-switched lasers are an sophisticated type of pulsed laser system. They use specialized techniques to make high-energy light pulses with extraordinary peak power. These advanced systems use either active or passive Q-switching to create intense, short optical pulses. These pulses are key for many industrial, scientific, and medical uses.

Q-switched lasers’ biggest advantage is their ability to store optical energy for long periods. Then they release it in concentrated bursts—peak powers way higher than continuous-wave lasers. Since the early 1960s, this technology has come a long way. Gordon Gould first proposed the idea, and R.W. Hellwarth and F.J. McClung built the first working Q-switched ruby laser. Today, Q-switched lasers are must-have tools in many fields. These include materials processing, medical treatments, scientific research, and defense.

Q-switching works by temporarily stopping laser oscillation. This lets energy build up on the gain medium. Then it releases that stored energy fast—as an intense optical pulse. "Q-switching" means changing the laser resonator’s quality factor (Q-factor). A high Q-factor means low optical losses—low Q-factor means high losses. During energy storage, resonator losses stay high. This stops laser action while the gain medium gets constant pumping.

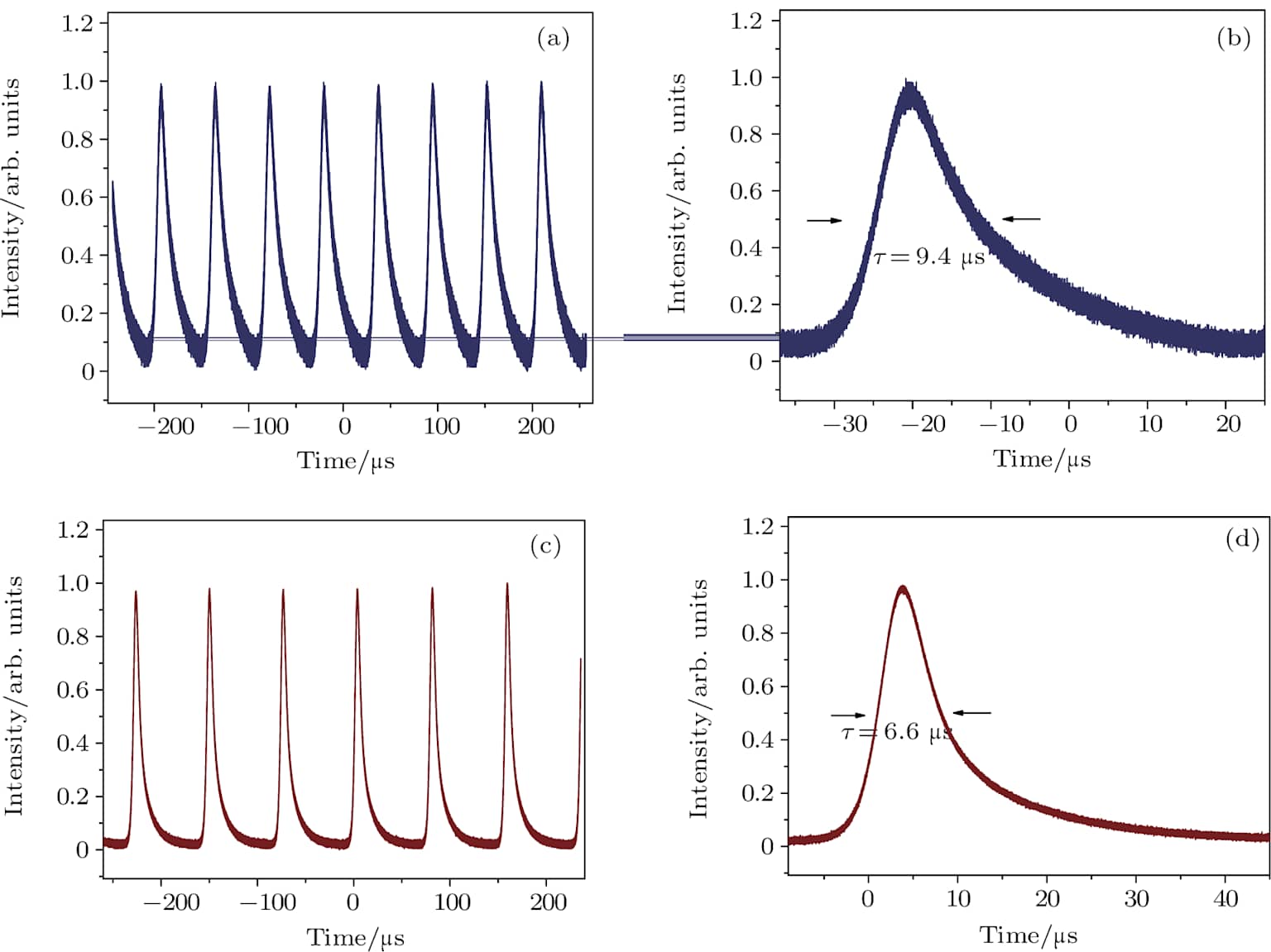

The process starts with the laser gain medium being pumped. Optical losses are kept high, so lasing doesn’t start. Energy builds up. When stored energy hits optimal levels, cavity losses drop suddenly. Intracavity power shoots up from spontaneous emission noise. This continues until gain saturates. Then the pulse reaches its peak and fades as energy is extracted. Q-switched pulses have sharp rise times and clear shapes. Durations range from nanoseconds to microseconds—depends on laser setup and settings. Pulse energy and duration tie to how much energy is stored and cavity dynamics during switching.

For Q-switching to work well, the laser gain medium needs specific traits. These let it store energy efficiently. The gain medium’s upper-state lifetime must be long enough. This lets it build up lots of energy without losing it on spontaneous emission. Also, saturation energy needs a careful balance. Too low, and you get too much gain and early lasing. Too high, and extracting energy becomes hard.

Pumping setup matters a lot for Q-switched laser performance. Continuous pumping is better for high repetition rates. Pulsed pumping with flashlamps is cheaper for low repetition rates—where peak power matters more than average power. Choosing between diode and lamp pumping depends on what you need. Diode pumping gives better beam quality and less thermal effects at high powers.

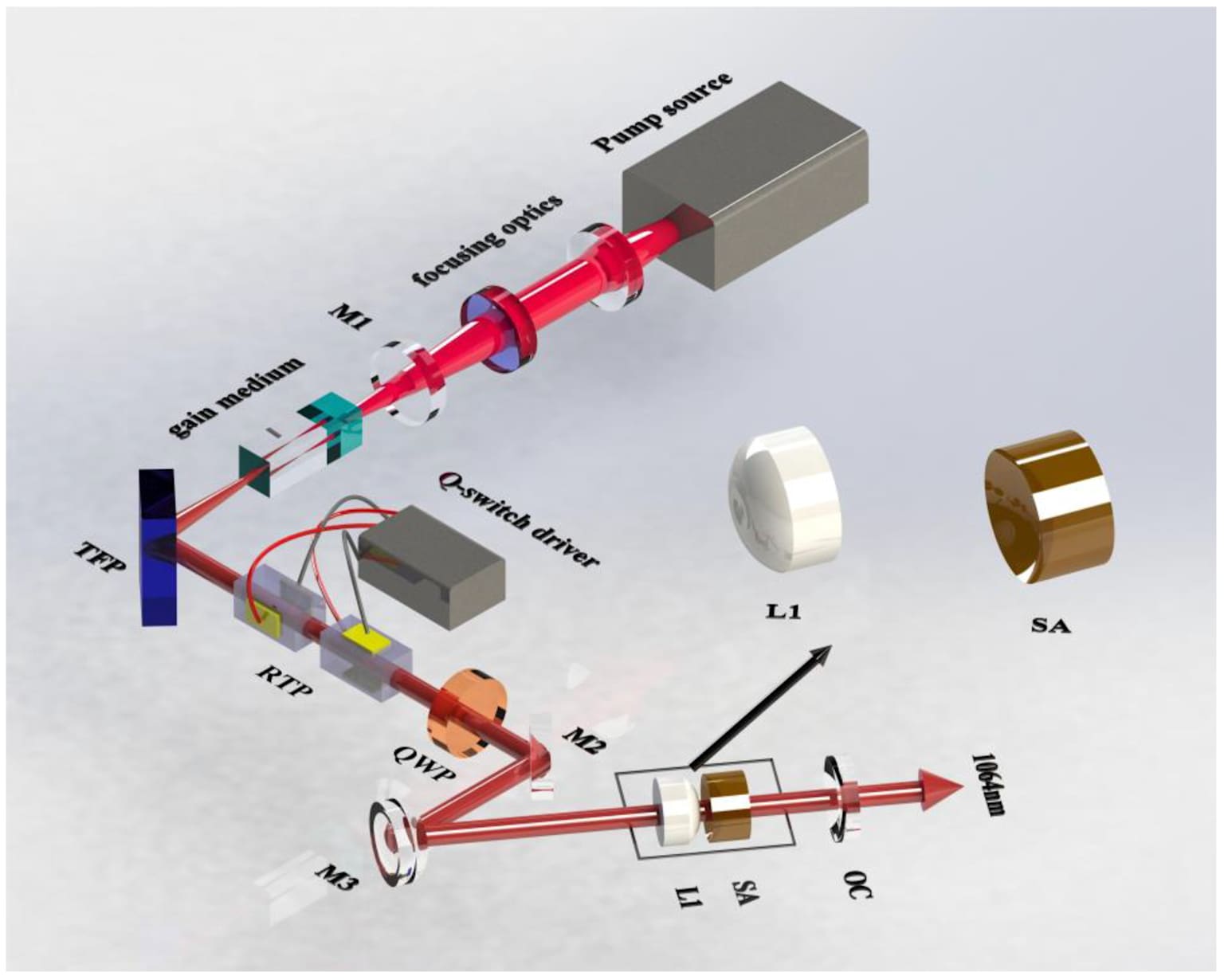

Active Q-switched solid-state lasers are the most common and versatile type. These lasers have an active optical modulator in the resonator cavity. It’s usually an acousto-optic or electro-optic device. This modulator controls pulse timing and traits precisely. Solid-state gain media are great for an energy storage. They can keep population inversion for long periods without losing much energy on fluorescence.

The most common active Q-switched systems use neodymium-doped crystals like Nd:YAG, Nd:YVO₄, and Nd:YLF. They operate in the 1-μm spectral region. These materials store energy well, have high optical gain, and handle heat well. Nd:YAG lasers are super versatile. They can make pulse energies from microjoules to several millijoules. Peak powers hit tens of kilowatts.

Acousto-optic Q-switches are the preferred active switching tech. They’re reliable, switch fast, and work at high repetition rates. These devices can switch in nanoseconds and support rates over 100 kHz. The acoustic wave in the modulator crystal creates a periodic refractive index change. This diffracts the intracavity beam, controlling cavity losses.

Passive Q-switching is simpler and cheaper then active systems. It uses saturable absorber materials that start and control the process automatic. For an 1-μm lasers, the most common saturable absorber is Cr⁴⁺:YAG. It absorbs strongly at the lasing wavelength—but absorption drops as optical intensity goes up.

Semiconductor saturable absorber mirrors (SESAMs) have changed passive Q-switching. They’re great for microchip laser setups. These devices combine a saturable absorber and high-reflectivity mirror in one. This makes ultra-compact laser designs possible. SESAM-based Q-switched microchip lasers can get pulse durations as short as a few hundred nanoseconds. Repetition rates range from kilohertz to megahertz.

Passive Q-switched lasers perform worse than active ones. The saturable absorber dissipates energy. But they’re simple, compact, and cheap. This makes them good for applications where moderate pulse energies and average powers are enough.

Q-switched fiber lasers are an specialized type. They use optical fibers’ unique properties as an gain media. They have advantages—likes great beam quality and efficient heat dissipation. But they also have limit. Nonlinear effects and damage thresholds restrict pulse energy and peak power.

High gain in fiber lasers can cause complex pulse dynamics. This leads to temporal substructures that hurt pulse quality. Also, single-mode fibers have small mode areas. This limits peak power—too high and you get nonlinear effects or optical damage. Master oscillator fiber amplifier (MOFA) setups help. They combine a low-power Q-switched seed laser with high-power fiber amplifiers.

Q-switched lasers perform across wide range of parameters. This let them work for many different applications. Pulse energy go from nanojoules (in small microchip systems) to several millijoules (in high-power solid-state setups). Pulse duration is usually on the nanosecond range. Some systems get sub-nanosecond or longer microsecond pulses—depend on cavity design and operating settings.

Peak power is a key metric for many Q-switched laser uses. Modern systems can hit kilowatts to megawatts. The relationship between pulse energy, duration, and peak power is simple: P_peak = E_pulse / τ_pulse. Optimizing cavity parameters lets you tailor these traits to your needs.

Repetition rates vary a lot. It depends on pumping scheme and thermal management. Low repetition rate systems (for maximum pulse energy) operate below 1 kHz. High repetition rate systems (for maximum average power) exceed 100 kHz.

Q-switched lasers cover a broad spectrum. They use different gain media and nonlinear frequency conversion. Fundamental wavelengths from laser crystals go from near-infrared to mid-infrared. Neodymium-doped crystals emit around 1064 nm. Erbium-doped materials emit around 1.65 μm and 2.94 μm.

Frequency conversion extends wavelengths to ultraviolet, visible, and more infrared. Second harmonic generation (SHG) converts 1064 nm to 532 nm green light. Third and fourth harmonic generation give 355 nm and 266 nm ultraviolet. High peak powers from Q-switched lasers make these processes efficient.

Sum and difference frequency generation, optical parametric oscillation, and amplification let you tune wavelengths. These techniques are great for accessing specific ranges. Like eye-safe wavelengths around 1.5 μm for ranging.

Materials processing is biggest market for Q-switched lasers. It make up about 35% of all uses. High peak power plus precise timing make Q-switched lasers perfect for many manufacturing processes. These includes cutting, drilling, marking, engraving, and surface modification.

Micromachining get a lot from Q-switched lasers’ unique traits. High peak power let you remove material efficiently via ablation. Short pulse duration keep heat-affected zones small and reduces thermal damage to nearby material. This is great for heat-sensitive materials and precise features.

Wavelength flexibility lets you optimize material absorption. Ultraviolet wavelengths (266 nm, 355 nm) work well for polymers and organic materials. They have high photon energy and strong absorption. Green wavelengths (532 nm) absorb well in copper and other metals. Near-infrared wavelengths (1064 nm) penetrate deep in transparent materials.

Medical uses are second biggest market for Q-switched lasers. They make up about 25% of total. Medicine love Q-switched lasers because they deliver precise, controlled energy. They do this with little damage on nearby tissues.

Dermatology use Q-switched lasers a lot. The selective photothermolysis principle let you destroy specific chromophores. It keep healthy tissue around them intact. Q-switched Nd:YAG lasers at 1064 nm and 532 nm work well for pigmented lesions. Like age spots, freckles, and acquired bilateral nevus of Ota-like macules.

Tattoo removal is one of the most successful medical uses. High peak power and short pulse duration fragment tattoo ink particles via photomechanical effects. Different wavelengths target different colors. 1064 nm for black and dark blue. 532 nm for red and orange. Other wavelengths for specialized colors.

Scientific research makes up about 15% of the Q-switched laser market. It focuses on spectroscopic techniques and fundamental studies. Laser-induced breakdown spectroscopy (LIBS) relies heavily on Q-switched lasers. High peak power density from focused pulses creates high-temperature plasmas for elemental analysis.

Time-resolved spectroscopy uses Q-switched lasers’ precise timing. Well-defined pulses let researchers study ultrafast processes in materials, chemicals, and biology. Pump-probe experiments have given insights into carrier dynamics in semiconductors and energy transfer in complex molecules.

Nonlinear optics research uses Q-switched lasers for high peak powers. These lasers pump optical parametric oscillators and amplifiers. This lets you generate tunable coherent radiation across broad spectra.

Defense and aerospace are specialized but critical markets. Range finding and target designation use Q-switched lasers’ high peak power and good beam quality. They achieve long-range detection. LIDAR systems for terrain mapping, atmospheric studies, and autonomous navigation use precise timing and high repetition rates.

Eye safety in military applications has driven development of 1.5 μm wavelengths. Atmospheric transmission is high, but eye damage is less than shorter wavelengths. Erbium-doped media and nonlinear conversion give access to these wavelengths while maintaining performance.

Q-switched lasers are usually Class 4. That’s highest risk category in international laser safety rules. High peak power plus possible high average power create many safety risks. You need an full risk management plan to handle them. Primary concerns are eye injury, skin damage, fire hazards, and indirect risks from electrical systems and chemicals.

Eye safety is biggest concern. Q-switched lasers can cause instant, permanent damage. Even brief exposure to unfocused beams can burn retinas and cause vision loss. High peak power makes them dangerous even at energy levels that are safe for continuous-wave lasers.

Skin exposure can cause thermal burns and damage. Ultraviolet wavelengths are worse—photochemical effects add to thermal damage. Short pulse duration causes photomechanical effects that need specialized treatment.

Comprehensive safety protocols need engineering controls, administrative procedures, and personal protective equipment. Laser safety eyewear is critical. But you need to choose it based on wavelengths and power levels. Standard glasses might not protect against high peak powers.

Interlock systems and beam containment are essential. They need to account for pulsed operation—like unexpected pulses during startup or malfunctions. Emergency shutdown procedures must be easy to access and understand.

Training for operators must cover pulsed laser hazards and operation. This includes beam path management, using protective equipment, emergency procedures, and recognizing hazard conditions.

New laser gain materials have opened up new possibilities for Q-switched lasers. They improves performance and expand uses. Advanced crystal growth and new doping methods let us make better gain media. These media stores energy better, cover more spectra, and handle heat better. Ytterbium-doped materials are promising for high-power Q-switched applications. They have good energy levels and less thermal loading.

Ceramic laser materials are an new alternative to traditional single-crystal media. They might be better for scaling manufacturing and changing composition. These materials can be made with uniform dopant distributions and complex geometries—hard to do with crystal growth.

System integration and miniaturization are driving Q-switched laser development. Advances in semiconductor manufacturing are making better SESAM devices. They have tailored absorption and improved damage thresholds. This makes ultra-compact lasers with performance that rivals larger systems.

MEMS technology is starting to be used in Q-switched lasers. Especially for compact, low-power applications. MEMS-based switches and modulators offer integrated Q-switching with smaller size, weight, and power consumption.

The global Q-switched laser market is growing fast. Projections say it will keep expanding due to more adoption across sectors. In 2024, it was valued at about $1.2 billion. It’s forecast to grow at 8.7% CAGR through 2033—reaching $2.5 billion.

AI and automation are influencing system design and operation. Smart lasers with automated parameter optimization, predictive maintenance, and adaptive control are emerging. They’re valuable for industrial and research uses.

Q-switched laser technology is now an mature, must-have tool in many industries and research fields. It have unique capabilities no other laser mode can match. Being able to make high-energy optical pulses with precise timing have led to breakthroughs in materials processing, medicine, research, and defense.

Continued development of advanced gain materials, better switching tech, and novel system architectures will expand Q-switched lasers’ capabilities and uses. Integration with AI, advanced manufacturing, and new optical materials will drive next-generation innovations.

As technology matures, safety, environmental impact, and cost-effectiveness will be more important in system design. Improving performance and expanding applications mean Q-switched lasers will stay at the forefront of photonic innovation for years to come.

Market dynamics and technological trends indicate strong growth across all major application sectors. As new uses emerge and existing ones demand higher performance, Q-switched lasers will evolve to meet these challenges—while keeping the reliability and precision that make them indispensable.

Contact: Jason

Phone: +8613337332946

E-mail: [email protected]

Add: Hangzhou City, Zhejiang Province, China