Laser crystals are one of the most critical parts on solid-state laser systems. They act as the active gain medium, turning optical pump energy into coherent laser light. These precisely engineered crystalline materials have changed countless applications. They’re used on medical surgery, industrial manufacturing, scientific research, and defense systems. As transparent crystals with laser-active dopants, they help amplify light on stimulated emission. This process is the foundation of how lasers work.

Laser crystals are optically transparent single crystals with carefully controlled amounts of laser-active ions. On solid-state lasers, these crystals work as gain media. They absorb energy on external pump sources and turn it into amplified, coherent laser light via stimulated emission. The host crystal matrix gives structural support. The dopant ions—usually trivalent rare earth elements like neodymium (Nd³⁺), ytterbium (Yb³⁺), or erbium (Er³⁺), or transition metal ions like titanium (Ti³⁺)—are the actual laser-active centers.

Crystalline gain media have a big advantage over materials like doped glasses. Their optical and thermal properties are better. Crystals usually have higher transition cross-sections—this makes light amplification more efficient. They also have narrower absorption and emission bandwidths—better for choosing wavelengths. Superior thermal conductivity helps manage heat. And they might have birefringence effects—good for specific uses.

When you shine optical pump light on laser crystals—usually from diode lasers or flash lamps—the dopant ions absorb pump photons. They move to excited energy states. Thanks to carefully designed energy levels, these excited ions can emit photons of a specific wavelength. This happens when they interact with passing photons of the same energy.

This stimulated emission process makes the optical signal stronger. The crystal acts as an optical amplifier on the laser resonator cavity. How efficient this process is and what it’s like depends a lot on the dopant ions and the host crystal matrix. The crystal matrix affects the electronic energy levels of the dopant ions via crystal field effects. It sets the phonon energy—this affects non-radiative transitions. And it gives the thermal and mechanical properties needed for stable laser operation.

There are many types of laser crystals. This lets you optimize for different uses—each family has unique benefits. Modern laser systems use crystals from several major families. Each has distinct structural and optical properties.

Garnet Crystals are the largest and most versatile family. Yttrium aluminum garnet (YAG) is the most widely used host matrix. The garnet structure (Y₃Al₅O₁₂) has exceptional chemical stability. It also has high thermal conductivity and optical isotropy. Neodymium-doped YAG (Nd:YAG) is still the most common laser crystal. It operates at 1064 nm—excellent efficiency and reliability for general uses. Ytterbium-doped YAG (Yb:YAG) is popular for high-power uses. It has a simple energy level structure and less quantum defect. This lets it reach power efficiencies over 80%.

Sapphire-based crystals have exceptional thermal and mechanical properties. Titanium-doped sapphire (Ti:sapphire) has the broadest tuning range of any laser crystal. It spans from 650 to 1100 nm—indispensable for ultrafast laser uses and spectroscopic research. Sapphire has superior thermal conductivity (46 W/m·K). This lets it operate at high power while keeping beam quality excellent.

Vanadate crystals like neodymium-doped yttrium vanadate (Nd:YVO₄) have much higher laser cross-sections than garnets. This lets them operate efficiently at lower pump powers. But their lower thermal conductivity (5.23 W/m·K) limits high-power uses.

Fluoride crystals like yttrium lithium fluoride (YLF) have unique benefits. They include excellent UV transparency, natural birefringence, and less thermal lensing. These properties make them great for frequency-doubled laser systems and uses that need minimal thermal distortion.

Tungstate crystals have moderate thermal conductivity and large gain bandwidths. This makes them great for broadband and tunable laser uses. Ytterbium-doped potassium gadolinium tungstate (Yb:KGW) shows what this family can do—high-power, broadly tunable laser systems.

Recent advances have made laser crystals more capable than traditional single-crystal materials. Ceramic laser gain media now have optical quality similar to single crystals. They also have advantages in manufacturing scale and dopant concentration control. Transparent ceramics can be larger than traditional crystals. They also have more uniform dopant distributions. This opens new doors for high-energy laser systems.

Co-doped crystal systems have multiple active ions. This lets them perform better or have new operating features. For example, saturable absorber crystals combine gain and absorption in one component. This makes compact passively Q-switched laser designs possible. These systems are less complex. But they also limit how flexible you can be—compared to separate gain and absorber parts.

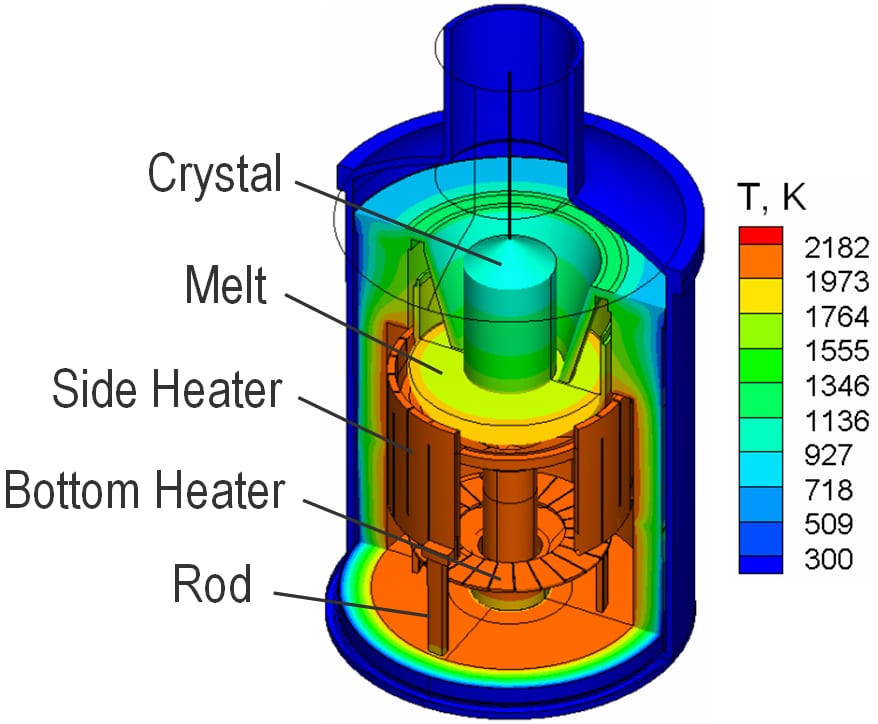

Laser crystal quality and performance depend a lot on how they’re made. Different growth methods are optimized for specific crystal types and uses.

The Czochralski method is still the main way to grow oxide laser crystals—especially garnets and sapphire. This process uses a seed crystal. You pull it slowly from a molten bath. You need precise temperature control and rotation. The method makes high-quality crystals—up to 6 inches in diameter. They have excellent optical homogeneity. Modern Czochralski systems have advanced temperature control. They also manage the atmosphere and monitor in real time. This ensures consistent crystal quality.

Other growth methods are for specialized uses and crystal types. The Kyropoulos method makes larger diameter crystals with shorter lengths. They’re ideal for optical components that need large apertures. Bridgman-Stockbarger techniques are good for fluoride crystals. These crystals don’t work with the high-temperature oxide crucibles used in Czochralski growth. Floating zone methods make the purest crystals. They do this by getting rid of crucible contamination. But they can only make smaller crystals.

The horizontal directed crystallization method is newer. It combines parts of multiple techniques. It makes high-quality crystals with good optical properties and reasonable growth rates. This method works well for crystals with tricky compositions or thermal properties.

After crystal growth, you need lots of processing. This turns raw crystal boules into precision optical parts. The process usually includes orientation, cutting, grinding, and polishing. You have to keep the crystal’s optical quality good. And you have to meet strict geometric specs.

Surface quality requirements change a lot depending on what you’re using the crystal for. Ultrafast and Q-switched lasers need the highest specs. This prevents optical damage and keeps beam quality good. Surface flatness tolerances often go beyond λ/10. For demanding uses, surface roughness has to be under 0.5 nm RMS. Polishing has multiple stages. You use finer abrasives each time. It ends with chemical-mechanical polishing. This gives you mirror-quality surfaces.

Geometric precision is just as important. For high-performance uses, parallelism and perpendicularity tolerances are measured in arc-seconds. These tight specs make sure the beam propagates properly. They also prevent thermal stress during operation.

Laser crystals let you do many medical procedures. They can generate specific wavelengths. These wavelengths are optimized for different tissue interactions and surgical needs.

Neodymium-doped crystals operating at 1064 nm penetrate deep into tissue. They’re used on laser surgery, tumor ablation, and cosmetic treatments. The 1064 nm wavelength goes through blood and water well. It also provides controlled heating for tissue coagulation.

Erbium-doped crystals emit at 1645 nm. This wavelength targets the strong water absorption peak. They’re ideal for precise tissue ablation—minimal thermal damage to surrounding areas. This "eye-safe" wavelength lowers the risk of retinal damage. It also makes operation safer in medical settings.

Holmium-doped crystals at 2100 nm absorb well in water and soft tissues. They’re great for urological procedures—like kidney stone fragmentation and prostate surgery. The wavelength can be sent through optical fibers efficiently. This lets you do minimally invasive procedures.

Laser crystals are precise and reliable. They’ve changed manufacturing processes on many industries. They let you process materials with new levels of precision and efficiency.

High-power industrial lasers need ytterbium-doped crystals a lot. These crystals are very efficient and manage heat well. Yb:YAG systems now often reach output powers over 10 kW. They’re used on metal cutting, welding, and additive manufacturing. The near-infrared wavelengths (1020-1070 nm) are efficiently absorbed by metals while allowing fiber delivery for flexible system configurations.

Ultrafast laser processing uses titanium-sapphire and ytterbium-doped crystals. They generate femtosecond pulses for precision micromachining. These systems let you do "cold processing"—minimal heat-affected zones. You can drill, cut, and texture surfaces precisely. Materials range from metals to semiconductors.

Laser crystals keep pushing the limits of scientific research. They also help make critical defense technologies.

Spectroscopic applications get help from titanium-sapphire crystals’ broad tunability. These crystals let you excite and analyze specific wavelengths across the near-infrared spectrum. Recent advances in phonon-assisted lasing have extended operational wavelengths. They go beyond traditional fluorescence limits. This opens new spectroscopic windows.

High-energy laser systems for research use large-aperture crystals and advanced cooling. They reach peak powers over terawatts. These systems let you do fundamental physics research. Like plasma physics, nuclear fusion studies, and high-field science.

Laser crystal geometry affects system performance a lot. Different designs are optimized for specific operating conditions and needs.

Brewster angle configurations get rid of reflection losses for p-polarized light. They also have the highest damage thresholds for high-power and ultrafast uses. The angled surfaces don’t need optical coatings. This reduces complexity and cost. It also maximizes performance for demanding applications. But Brewster-cut crystals need more material and precise alignment. This makes manufacturing costs higher.

Right-angle cuts with anti-reflection coatings are easier to align. They also cost less. But they might limit damage thresholds. And they add complexity because of the coating requirements. These designs work well for lower-power uses. Where cost and simplicity are more important than ultimate performance.

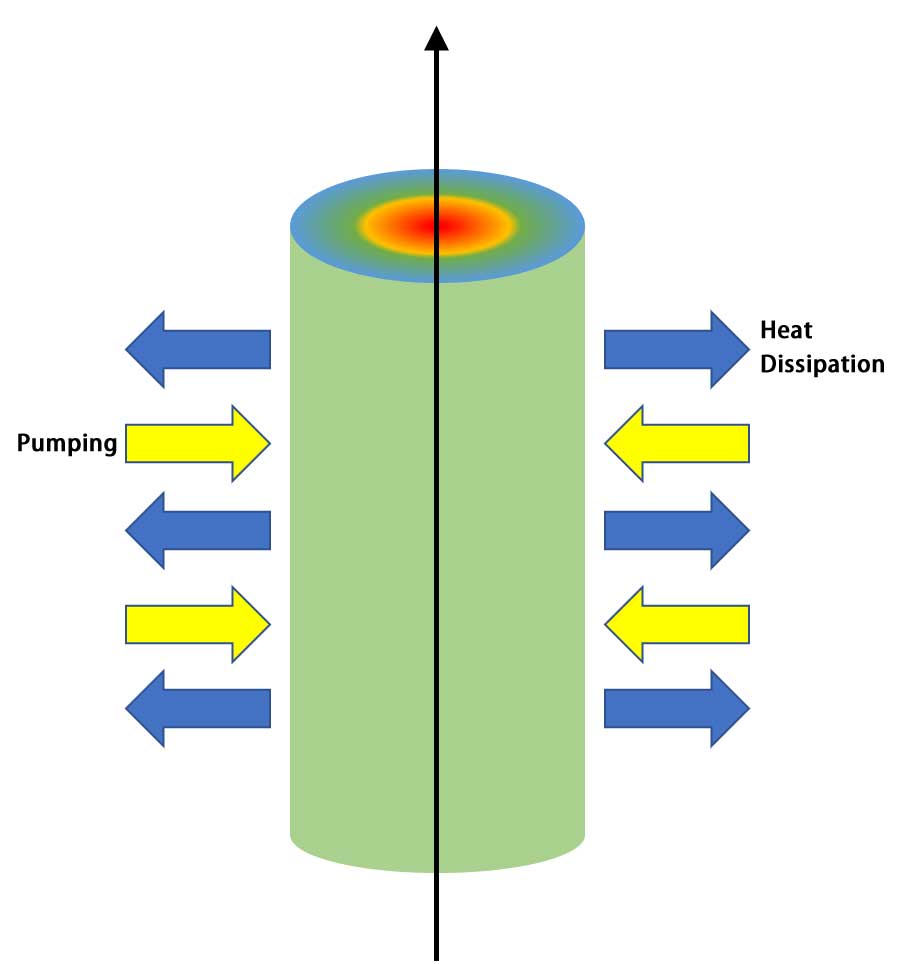

As laser power goes up, effective thermal management gets more important. You need to think carefully about crystal properties and system design.

Thermal conductivity is different for each crystal type. Sapphire has the highest (46 W/m·K). Then garnets (14 W/m·K) and vanadates (5.23 W/m·K). Higher thermal conductivity lets you remove heat better. It also reduces thermal lensing—this can ruin beam quality.

Thermal stress tolerance depends on the crystal’s material properties and how it’s mounted. Advanced cooling techniques—like cryogenic operation and active thermal management—let you scale power. You can keep beam quality good and the crystal intact.

The field of laser crystals is changing fast. New materials, growth techniques, and applications are coming out all the time.

Photonic time crystals are a new type of material. They could amplify light exponentially using temporal periodicity—instead of spatial. These exotic materials change how we understand light-matter interactions. They could make lasers more efficient than ever before.

Ceramic processing advances keep making polycrystalline gain media better. Their optical quality and size capabilities improve. This could let you make larger aperture systems for less money. Ceramic processing lets you control dopant distributions precisely. You can also make complex compositions. This opens new doors for engineered laser materials.

Advanced growth techniques—like laser-assisted crystal growth and new ambient control systems—could make crystals better. They also promise lower manufacturing costs. These advances could make high-performance laser crystals easier to get. They’re for emerging uses—on autonomous vehicles, consumer electronics, and distributed manufacturing.

Laser crystals are remarkable examples of materials engineering. Precise control of atomic composition and structure lets them have extraordinary optical performance. From the fundamental physics of stimulated emission to modern application demands, these materials keep pushing what’s possible with coherent light sources.

New crystal types, better manufacturing processes, and advanced system designs are being developed. This ensures laser crystals will stay at the forefront of photonic technology. They’ll enable innovations that shape the future of manufacturing, medicine, scientific research, and many other fields. As applications get more demanding and diverse, choosing and optimizing laser crystal materials carefully gets more critical. This helps achieve optimal performance in each specific use.

Contact: Jason

Phone: +8613337332946

E-mail: [email protected]

Add: Hangzhou City, Zhejiang Province, China